Fabrication

is a Measure of

Success.

Technical Parameters

|

Model NO. |

CS86745167451 |

Standard |

ASTM, JIS, GB, AISI, DIN, BS, AISI, ASTM, DIN, JIS, GB, BS |

|

Certification |

ISO, RoHS, IBR |

Surface Treatment |

Polished |

|

Technique |

Heat Treatment |

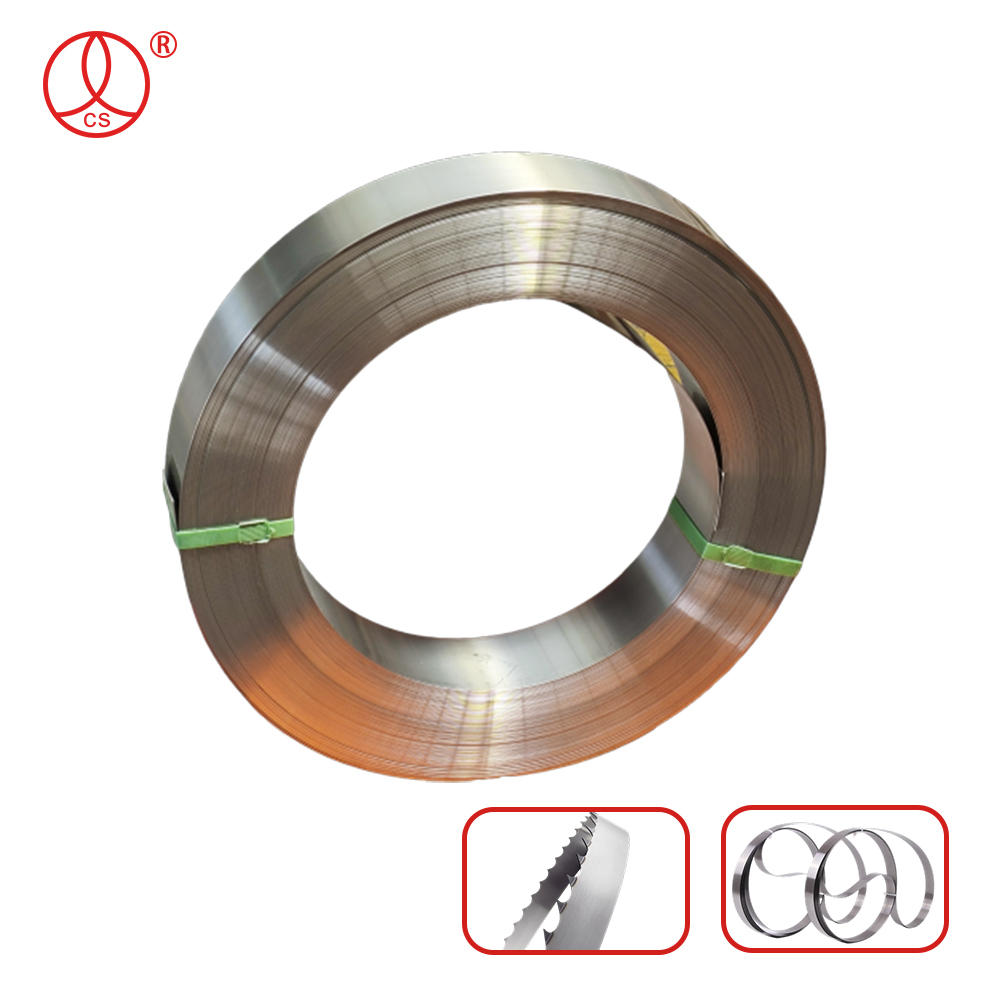

Application |

Saw Blade, Band Saw Blade, Cutting Tools.etc |

|

Edge |

Sheared Edge/Square Edge/Round Edge/Customized, Sheared/Square/Round |

Stock |

Yes |

|

Type |

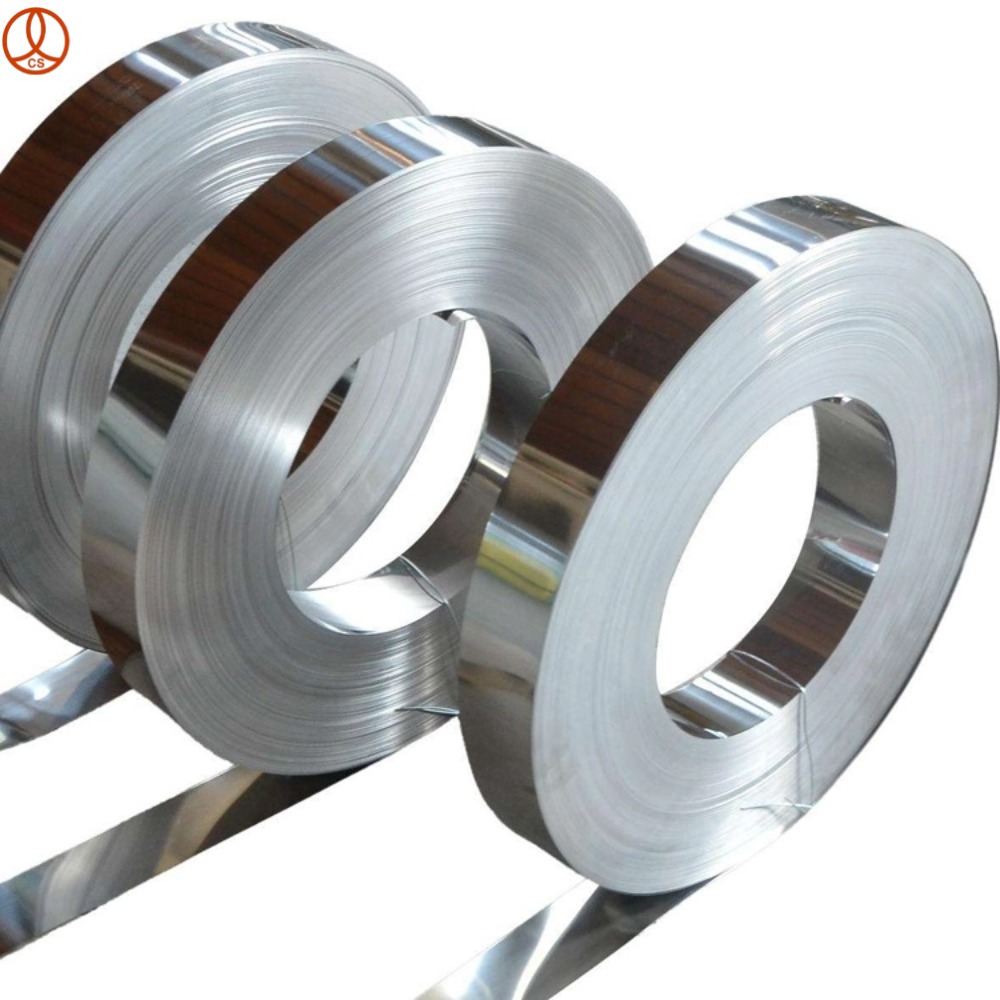

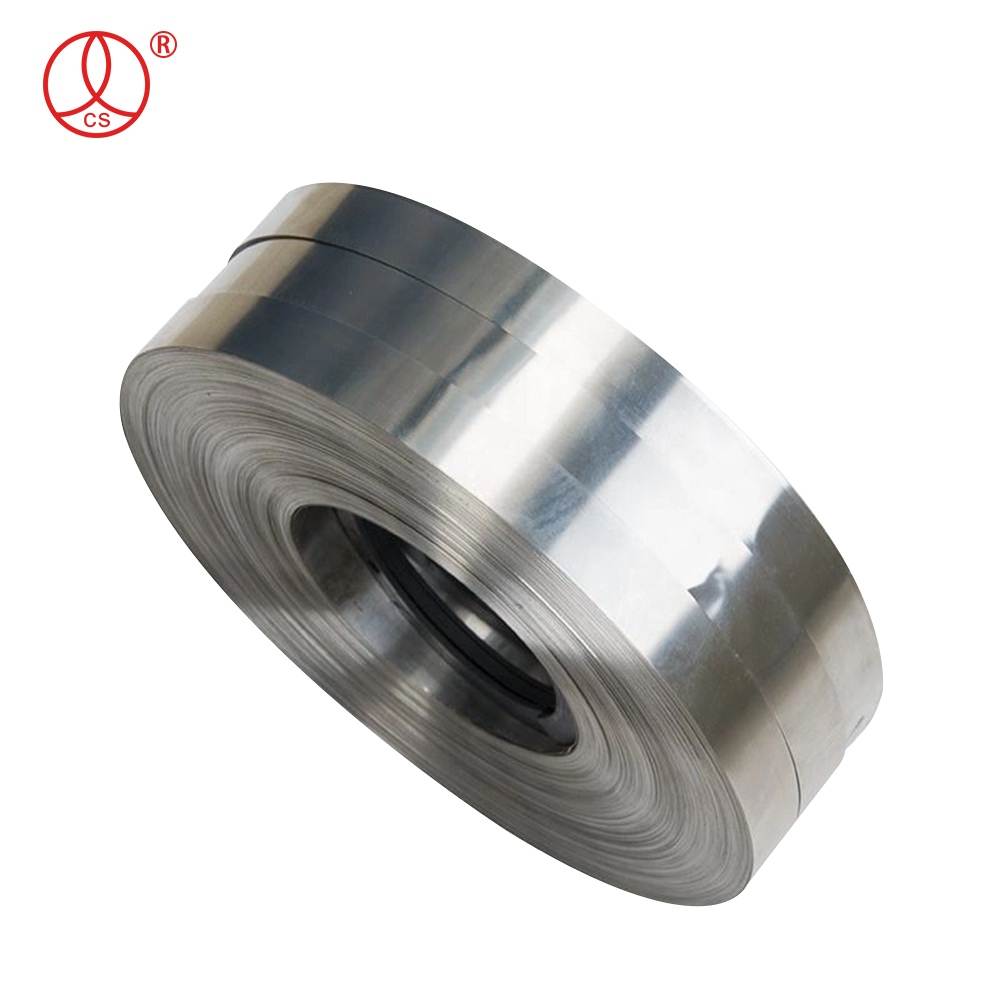

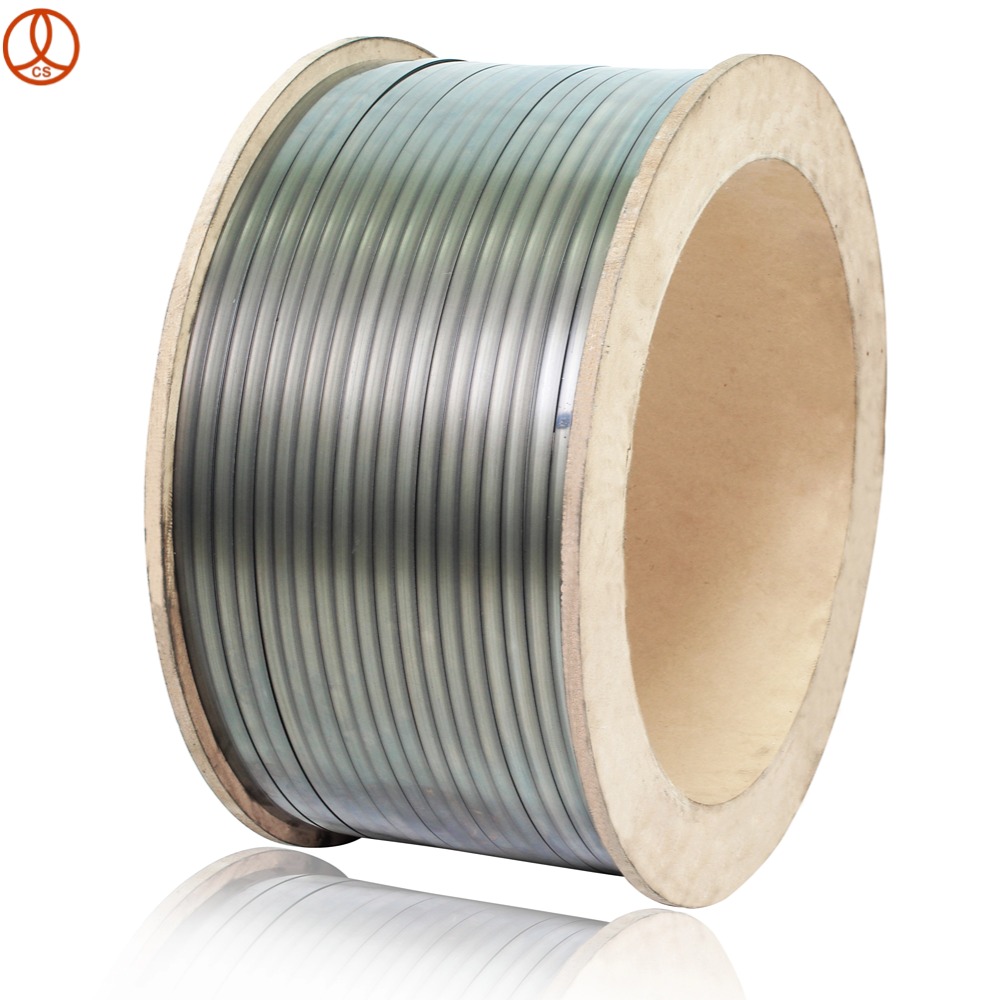

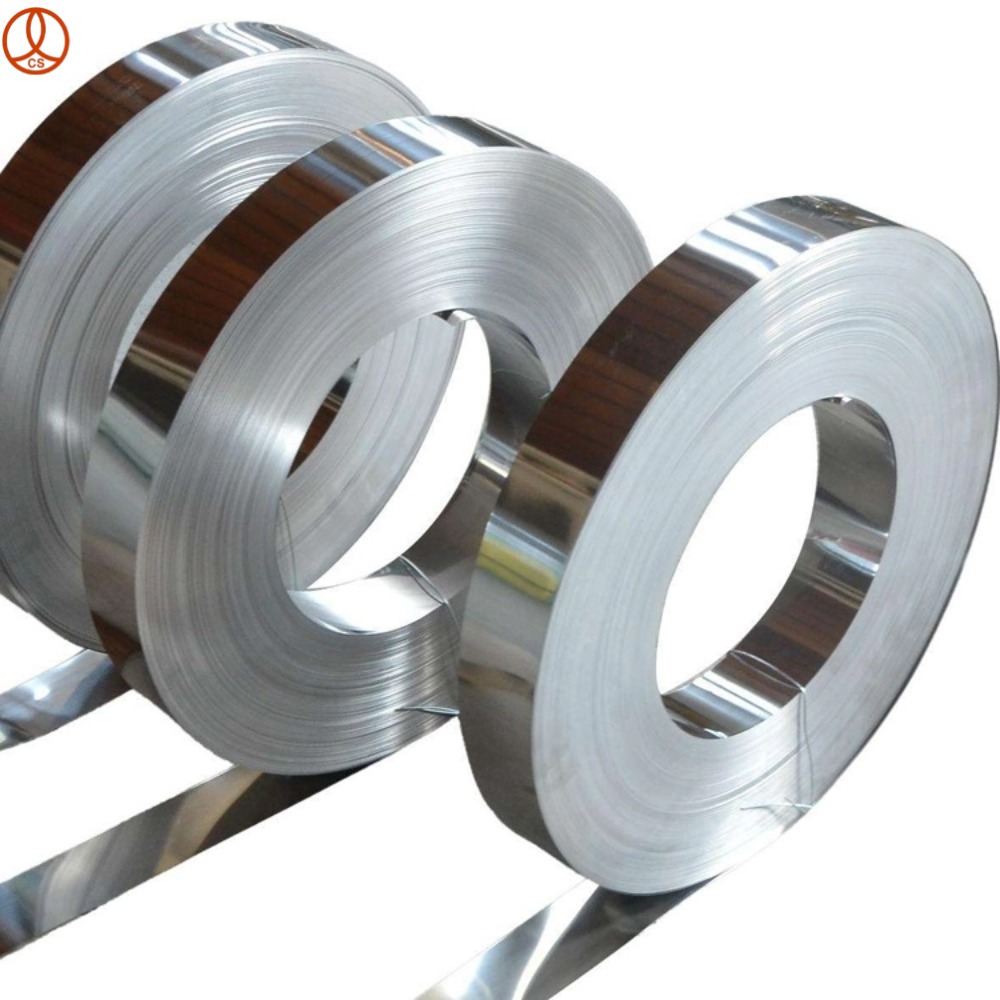

Coil |

Quality |

High Quality |

|

Composition |

Carbon Steel |

Tolerance |

±10% |

|

Processes |

Heat Treatment, Polishing, Edge Treatment, Laser Printing, Packaging |

Surface Finishing

|

Blue, Polishied-Bright.etc

|

|

Brand Name |

Chang Sheng |

Width |

16-160mm/Customized |

|

Length |

According to The Client′s Request |

Hardness |

40-50 HRC |

|

Steel Color |

White/Blue/Yellow |

MOQ |

4 Tons |

|

Delivery Time |

25-30days After Received The Deposits |

Package |

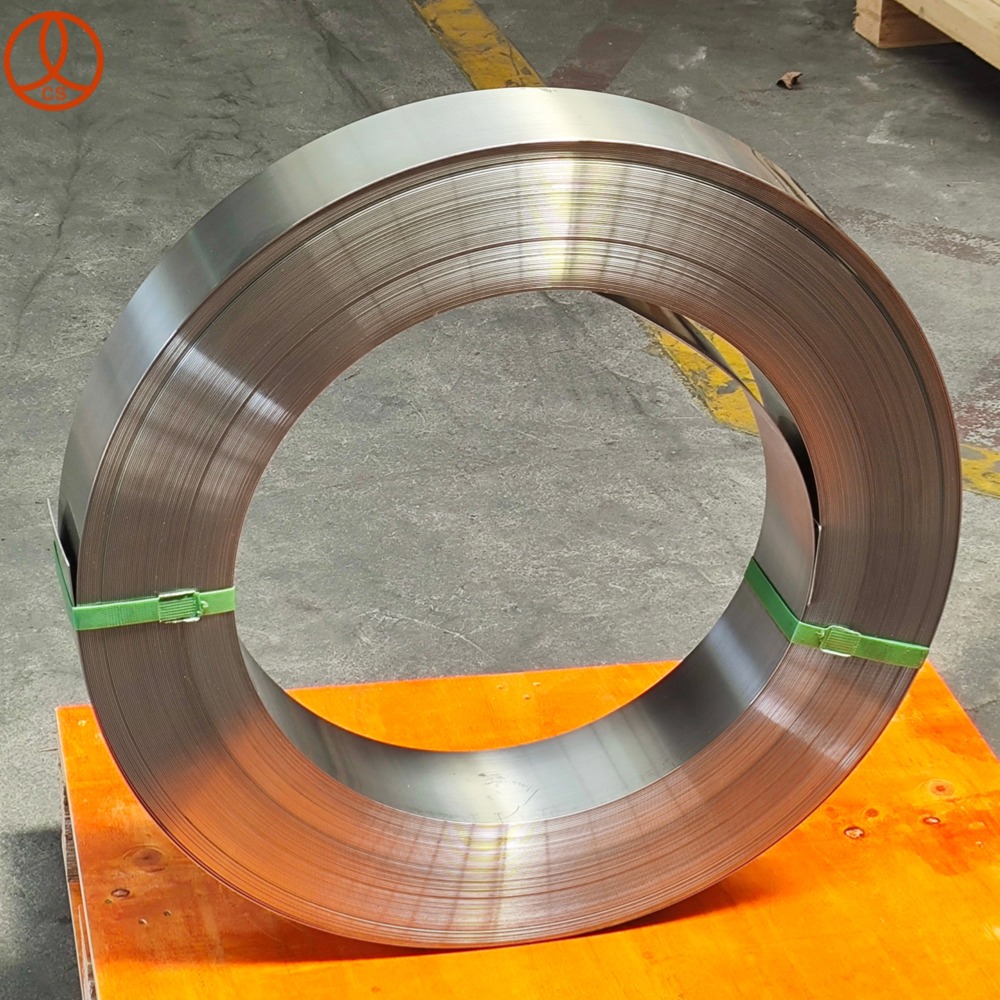

Each Bundle with Light Oil and Anti-Rust Paper |

|

Origin |

China |

HS Code |

7312900000 |

|

Production Capacity |

20000/TONS Years |

Variety |

CN(50#/75# T8A/T10A) |

|

Variety |

JP(SK65/SK75/SK85/SK95) |

Variety |

DE(CK75/C75S/C85S/C90S) |

Technical Parameters

|

Model NO. |

CS86745167451 |

Standard |

ASTM, JIS, GB, AISI, DIN, BS, AISI, ASTM, DIN, JIS, GB, BS |

|

Certification |

ISO, RoHS, IBR |

Surface Treatment |

Polished |

|

Technique |

Heat Treatment |

Application |

Saw Blade, Band Saw Blade, Cutting Tools.etc |

|

Edge |

Sheared Edge/Square Edge/Round Edge/Customized, Sheared/Square/Round |

Stock |

Yes |

|

Type |

Coil |

Quality |

High Quality |

|

Composition |

Carbon Steel |

Tolerance |

±10% |

|

Processes |

Heat Treatment, Polishing, Edge Treatment, Laser Printing, Packaging |

Surface Finishing

|

Blue, Polishied-Bright.etc

|

|

Brand Name |

Chang Sheng |

Width |

16-160mm/Customized |

|

Length |

According to The Client′s Request |

Hardness |

40-50 HRC |

|

Steel Color |

White/Blue/Yellow |

MOQ |

4 Tons |

|

Delivery Time |

25-30days After Received The Deposits |

Package |

Each Bundle with Light Oil and Anti-Rust Paper |

|

Origin |

China |

HS Code |

7312900000 |

|

Production Capacity |

20000/TONS Years |

Variety |

CN(50#/75# T8A/T10A) |

|

Variety |

JP(SK65/SK75/SK85/SK95) |

Variety |

DE(CK75/C75S/C85S/C90S) |

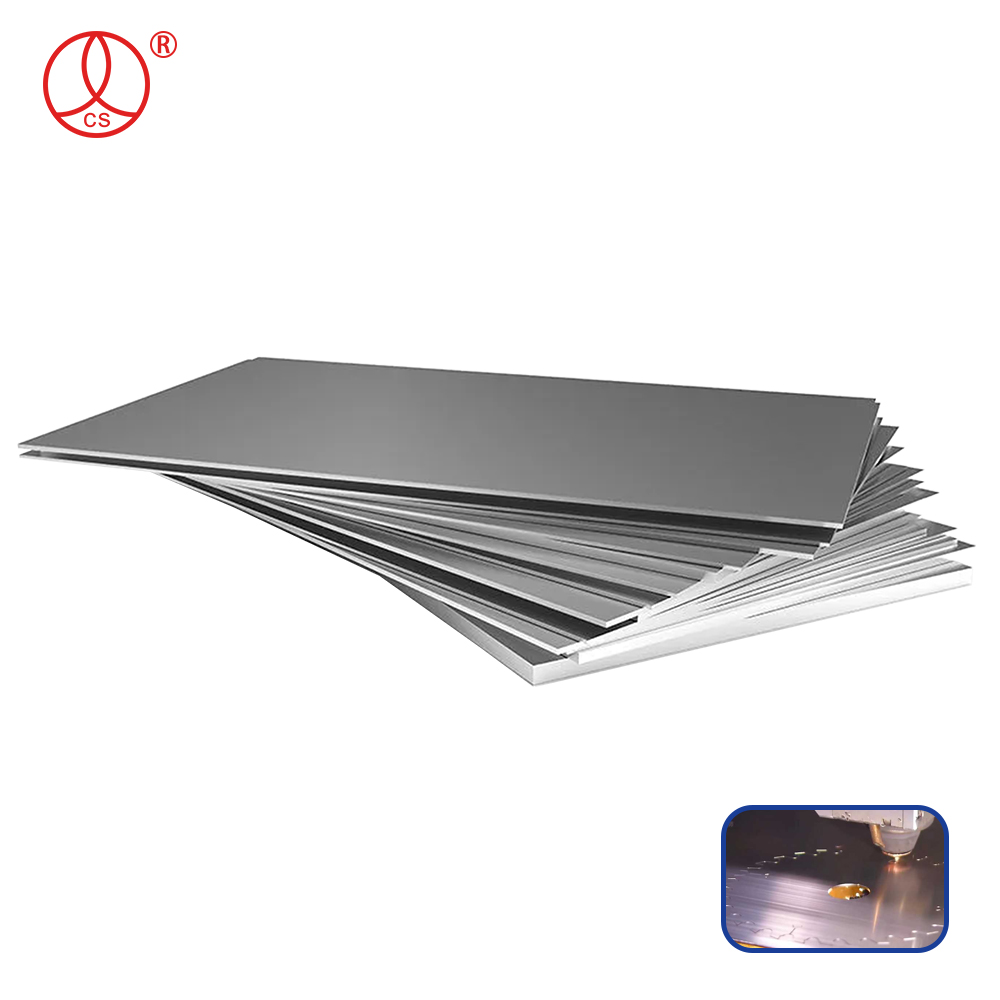

Product Description

If you want more details, please contact us here!

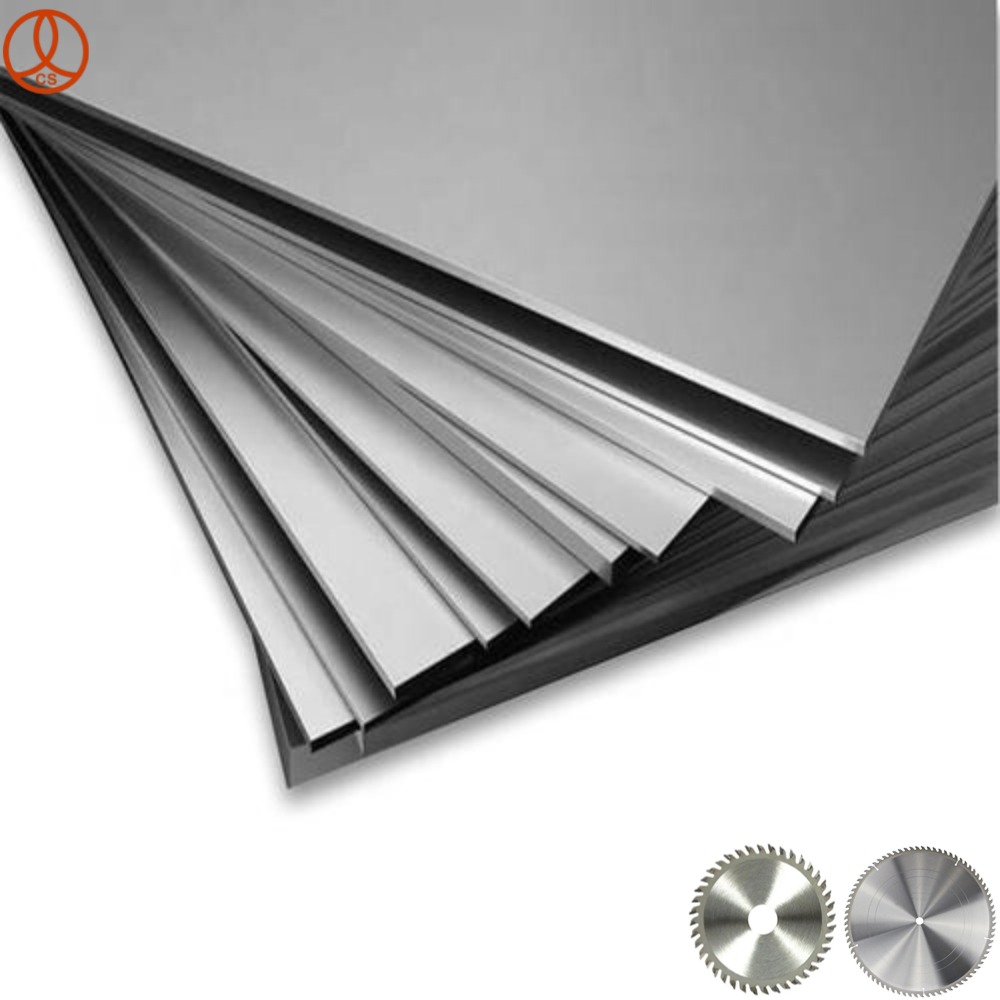

Advantages of Our High-Carbon Steel Strips

1. High strength:

High carbon steel has a high carbon content, usually between 0.6%-1.0%. This gives high carbon steel coils very high strength and hardness, and the ability to withstand greater mechanical stress and wear.

2. Strong wear resistance:

Due to its high hardness, high carbon steel coils perform well in abrasive environments and are widely used in parts that require high wear resistance, such as cutting tools, blades, springs, etc.

3. Good hardenability:

High carbon steel is easy to obtain uniform hardness and microstructure during heat treatment, giving it excellent mechanical properties after quenching.

4. Relatively low price:

Compared to alloy steel or stainless steel, high carbon steel is generally more affordable and is a cost-effective material choice in certain applications that require high strength and wear resistance.

Product Description

If you want more details, please contact us here!

Advantages of Our High-Carbon Steel Strips

1. High strength:

High carbon steel has a high carbon content, usually between 0.6%-1.0%. This gives high carbon steel coils very high strength and hardness, and the ability to withstand greater mechanical stress and wear.

2. Strong wear resistance:

Due to its high hardness, high carbon steel coils perform well in abrasive environments and are widely used in parts that require high wear resistance, such as cutting tools, blades, springs, etc.

3. Good hardenability:

High carbon steel is easy to obtain uniform hardness and microstructure during heat treatment, giving it excellent mechanical properties after quenching.

4. Relatively low price:

Compared to alloy steel or stainless steel, high carbon steel is generally more affordable and is a cost-effective material choice in certain applications that require high strength and wear resistance.

DongGuan ChangSheng Cutting Tools Co., Ltd. manufactures premium spring strip steel for demanding applications in automotive, electronics, and industrial tooling. Our cold-rolled strips deliver exceptional elasticity, fatigue resistance, and consistent performance.

DongGuan ChangSheng Cutting Tools Co., Ltd. manufactures premium alloy steel strips designed for superior strength, wear resistance, and durability in extreme operating conditions.

DongGuan ChangSheng Cutting Tools Co., Ltd. specializes in high-tech alloy steel strips that push the boundaries of cutting tool durability and industrial applications

DongGuan ChangSheng Cutting Tools Co., Ltd. produces high-performance saw blade steel matrix materials that set new standards in cutting tool durability and precision.

Heat Treatment High Carbon Steel Strip for Bandsaw Blade, Industrial Knife

Heat Treatment High Carbon Steel Strip for Bandsaw Blade, Industrial Knife

Heat Treatment High Carbon Steel Strip for Bandsaw Blade, Industrial Knife

Heat Treatment High Carbon Steel Strip for Bandsaw Blade, Industrial Knife

Heat Treatment High Carbon Steel Strip for Bandsaw Blade, Industrial Knife

Heat Treatment High Carbon Steel Strip for Bandsaw Blade, Industrial Knife

Heat Treatment High Carbon Steel Strip for Bandsaw Blade, Industrial Knife

Heat Treatment High Carbon Steel Strip for Bandsaw Blade, Industrial Knife

Heat Treatment High Carbon Steel Strip for Bandsaw Blade, Industrial Knife

Heat Treatment High Carbon Steel Strip for Bandsaw Blade, Industrial Knife

DongGuan ChangSheng Cutting Tools Co., Ltd. produces precision high carbon steel strips engineered for superior hardness, durability, and performance in demanding cutting tool manufacturing.

High-performance alloy steel strips for band saw blades with enhanced chromium/vanadium content. Delivers 50% longer lifespan than carbon steel. Custom grades & sizes available. Request specs.

DongGuan ChangSheng Cutting Tools Co., Ltd. produces precision saw blade matrices – the foundational steel cores that determine the durability and cutting performance of circular saw blades. Our specialized steel strips ensure vibration-free operation and extended blade life.

DongGuan ChangSheng Cutting Tools Co., Ltd. manufactures specialized strip steel for industrial die cutters, engineered for clean, precise cuts in thick cardstock, flip-top cigarette boxes, thin paper, and gray board applications.

DongGuan ChangSheng Cutting Tools Co., Ltd. produces high-accuracy etching knife dies specifically designed for embossing die manufacturers. Our chemically-etched dies deliver intricate patterns and consistent performance for foil stamping, leather embossing, and packaging applications.

DongGuan ChangSheng Cutting Tools Co., Ltd. produces premium spring steel strips specifically engineered for automotive windscreen wiper blades. Our cold-rolled steel strips deliver consistent pressure distribution and fatigue resistance for superior wiping performance.

DongGuan ChangSheng Cutting Tools Co., Ltd. manufactures premium spring strip steel for demanding applications in automotive, electronics, and industrial tooling. Our cold-rolled strips deliver exceptional elasticity, fatigue resistance, and consistent performance.

DongGuan ChangSheng Cutting Tools Co., Ltd. manufactures premium alloy steel strips designed for superior strength, wear resistance, and durability in extreme operating conditions.

DongGuan ChangSheng Cutting Tools Co., Ltd. specializes in high-tech alloy steel strips that push the boundaries of cutting tool durability and industrial applications

DongGuan ChangSheng Cutting Tools Co., Ltd. produces high-performance saw blade steel matrix materials that set new standards in cutting tool durability and precision.

Heat Treatment High Carbon Steel Strip for Bandsaw Blade, Industrial Knife

Heat Treatment High Carbon Steel Strip for Bandsaw Blade, Industrial Knife

Heat Treatment High Carbon Steel Strip for Bandsaw Blade, Industrial Knife

Heat Treatment High Carbon Steel Strip for Bandsaw Blade, Industrial Knife