Fabrication

is a Measure of

Success.

Technical Parameters

|

Model NO. |

CS867684563 |

Standard |

ASTM, JIS, GB, AISI, DIN, BS, AISI, ASTM, DIN, JIS, GB, BS |

|

Certification |

ISO, RoHS, IBR |

Surface Treatment |

Polished |

|

Technique |

Heat Treatment |

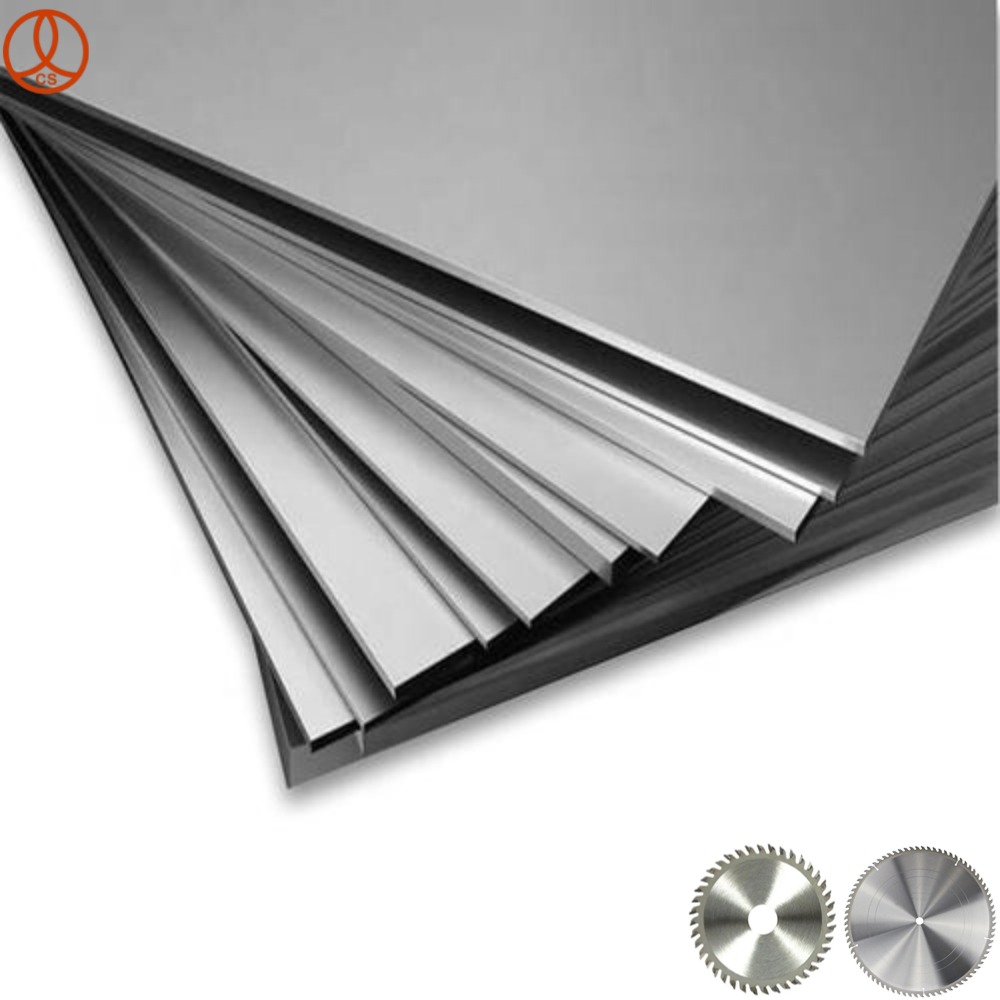

Application |

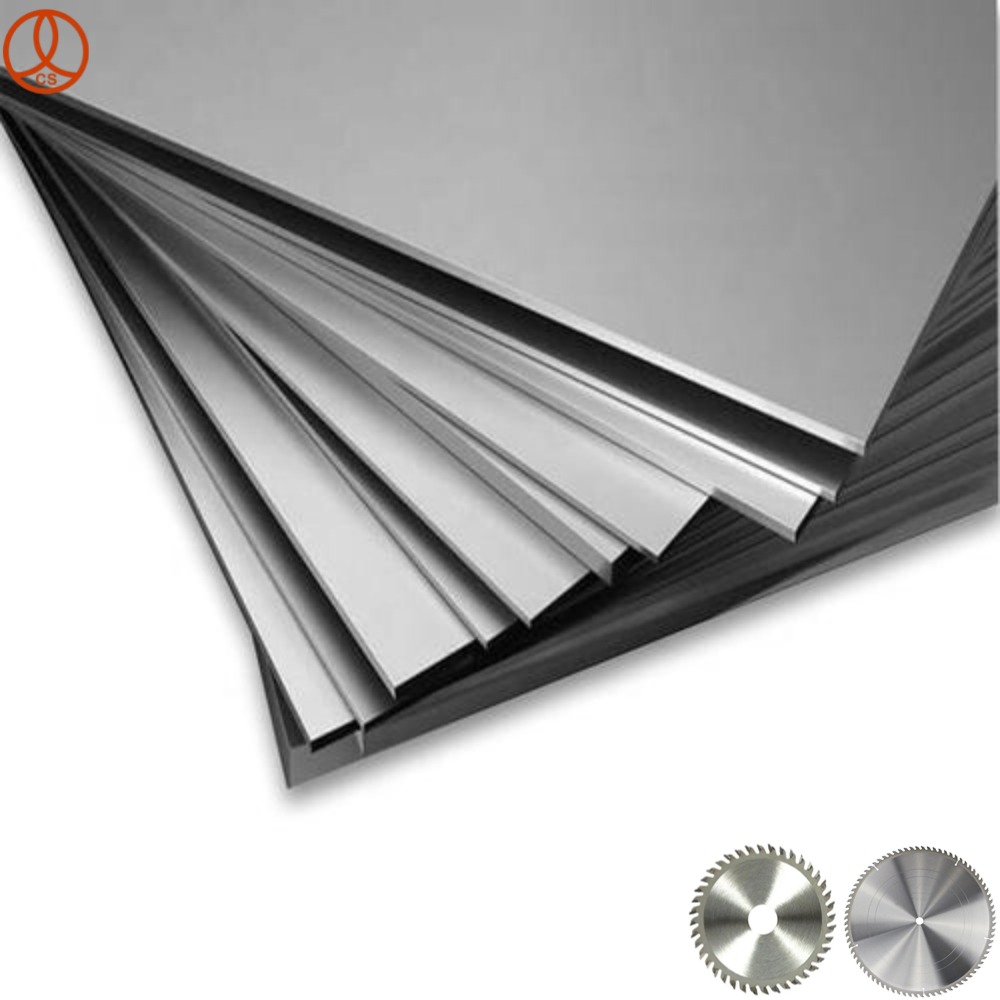

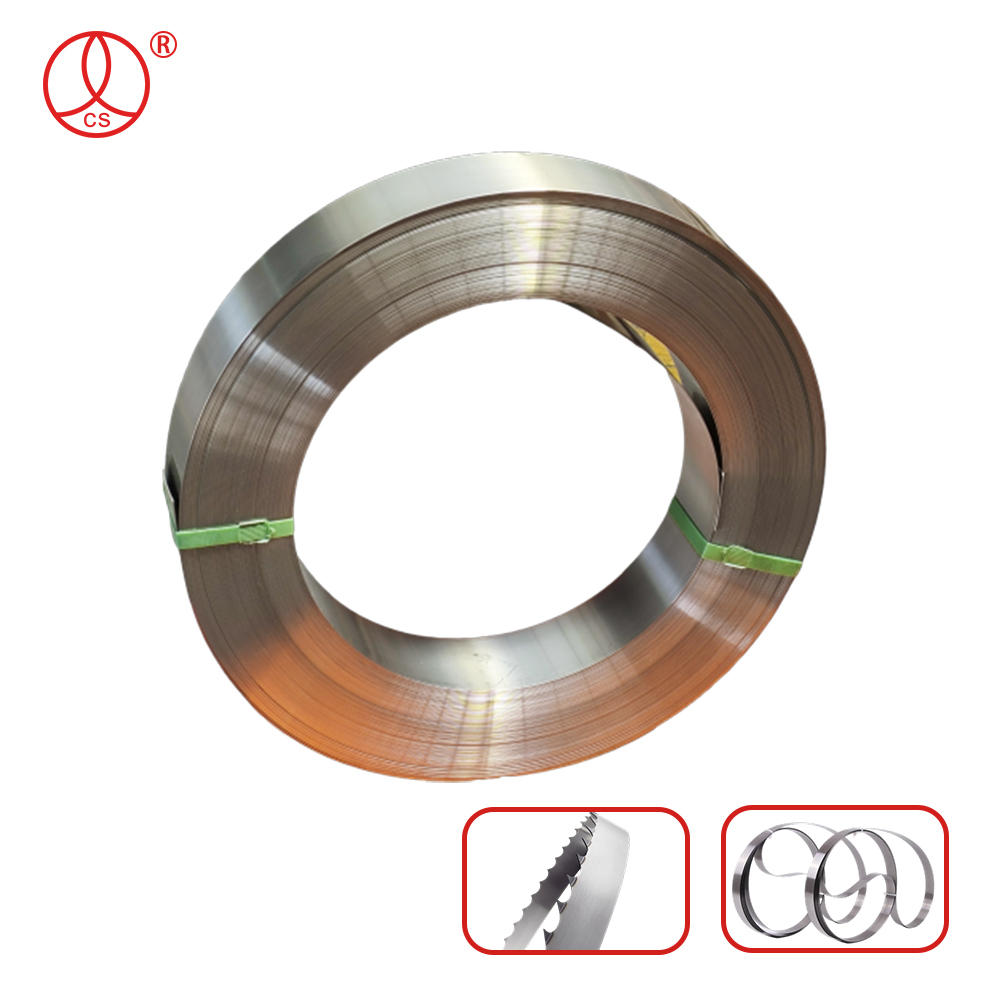

Saw Blade, Band Saw Blade, Cutting Tools, etc |

|

Edge |

Sheared Edge/Square Edge/Round Edge/Customized, Sheared/Square/Round |

Stock |

Yes |

|

Type |

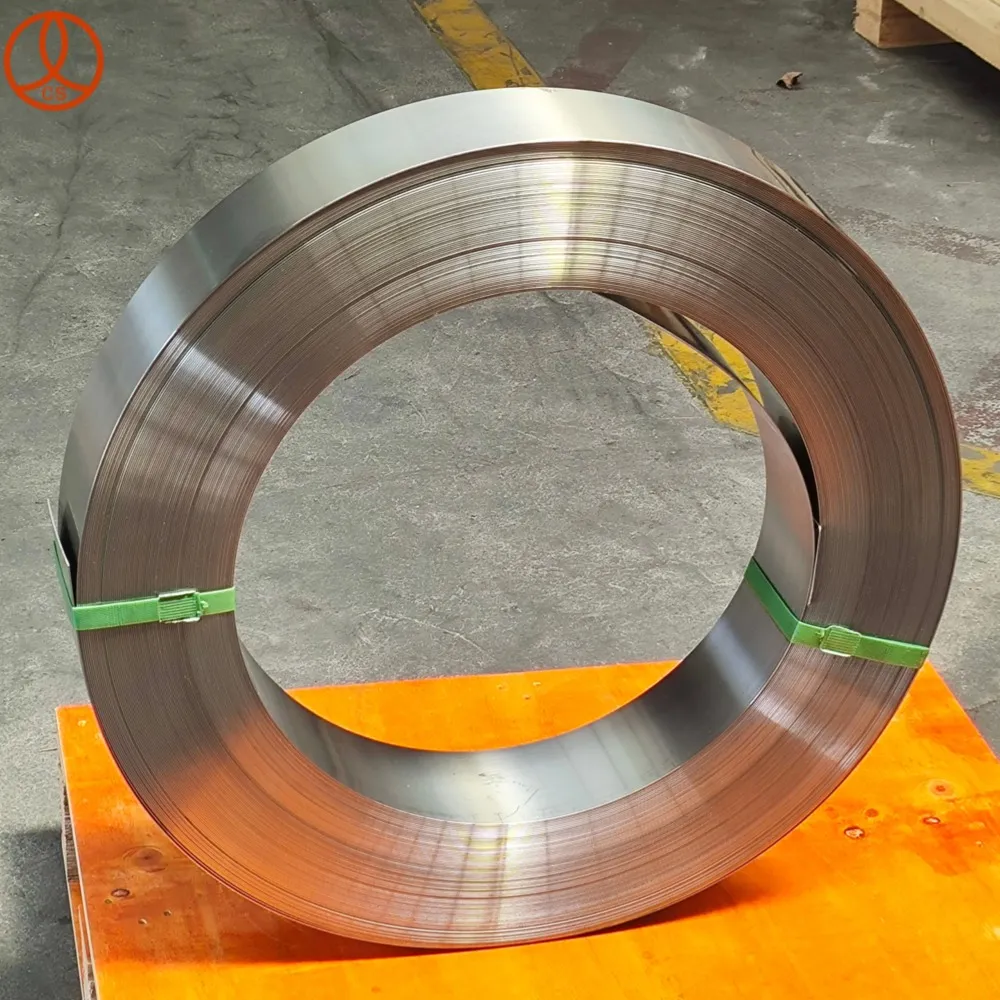

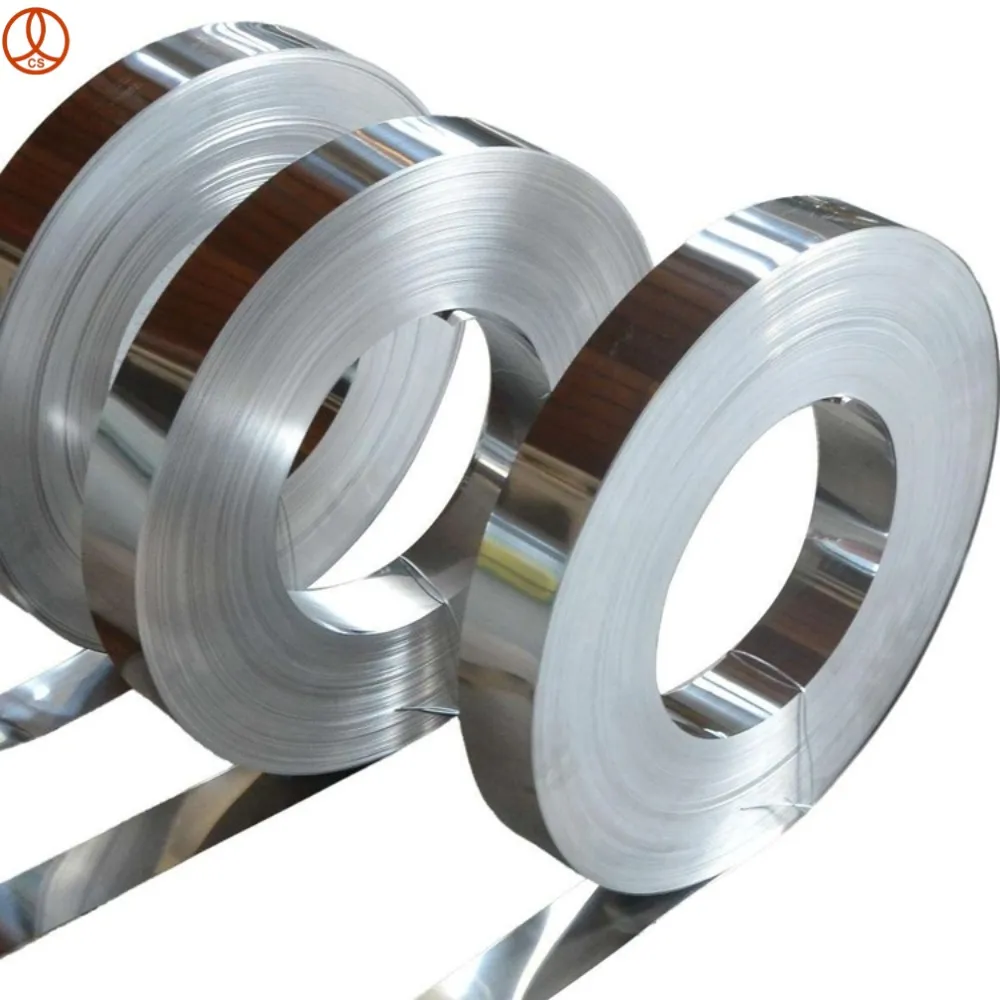

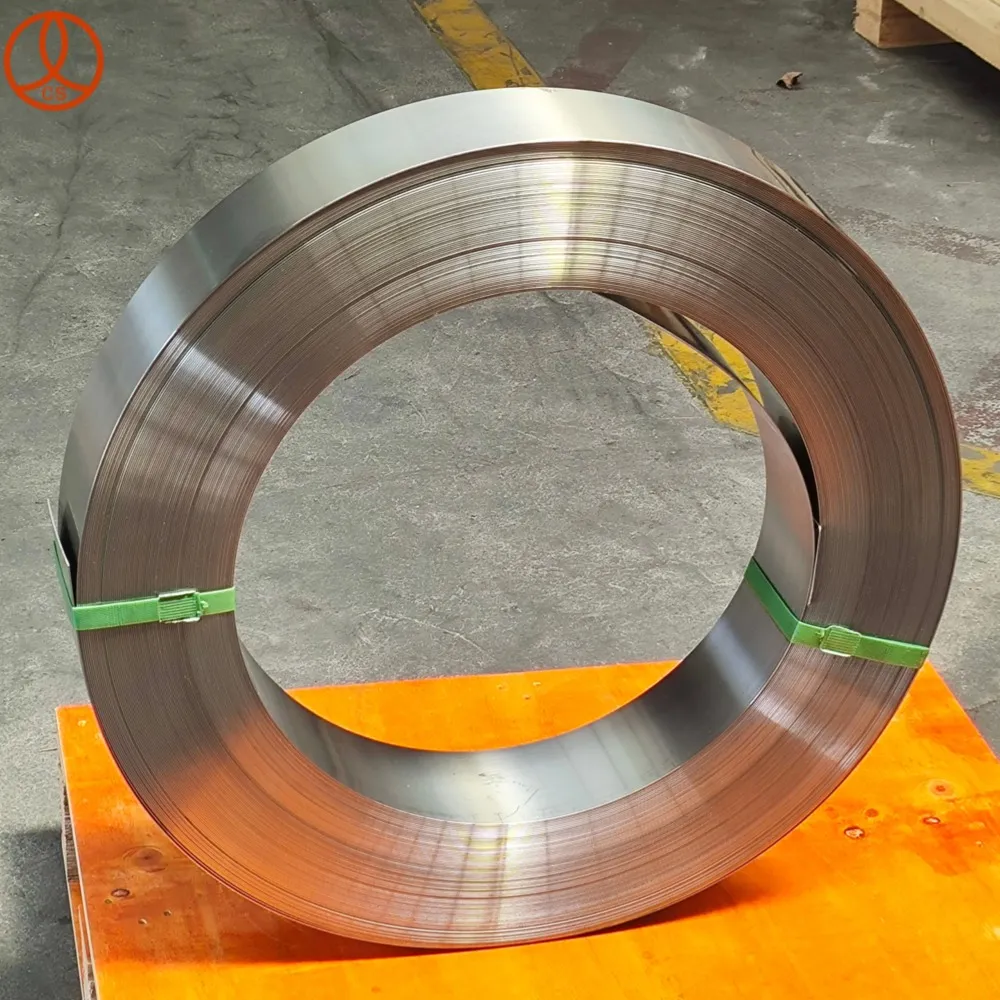

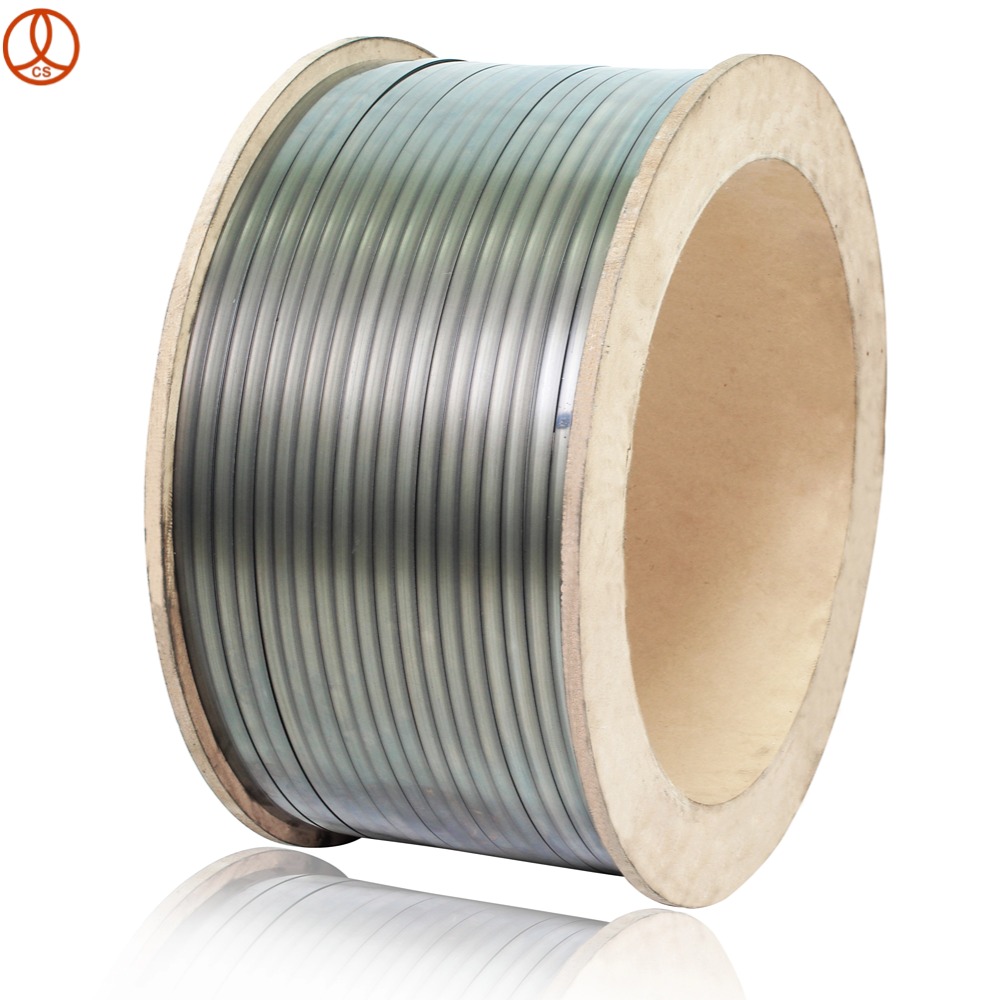

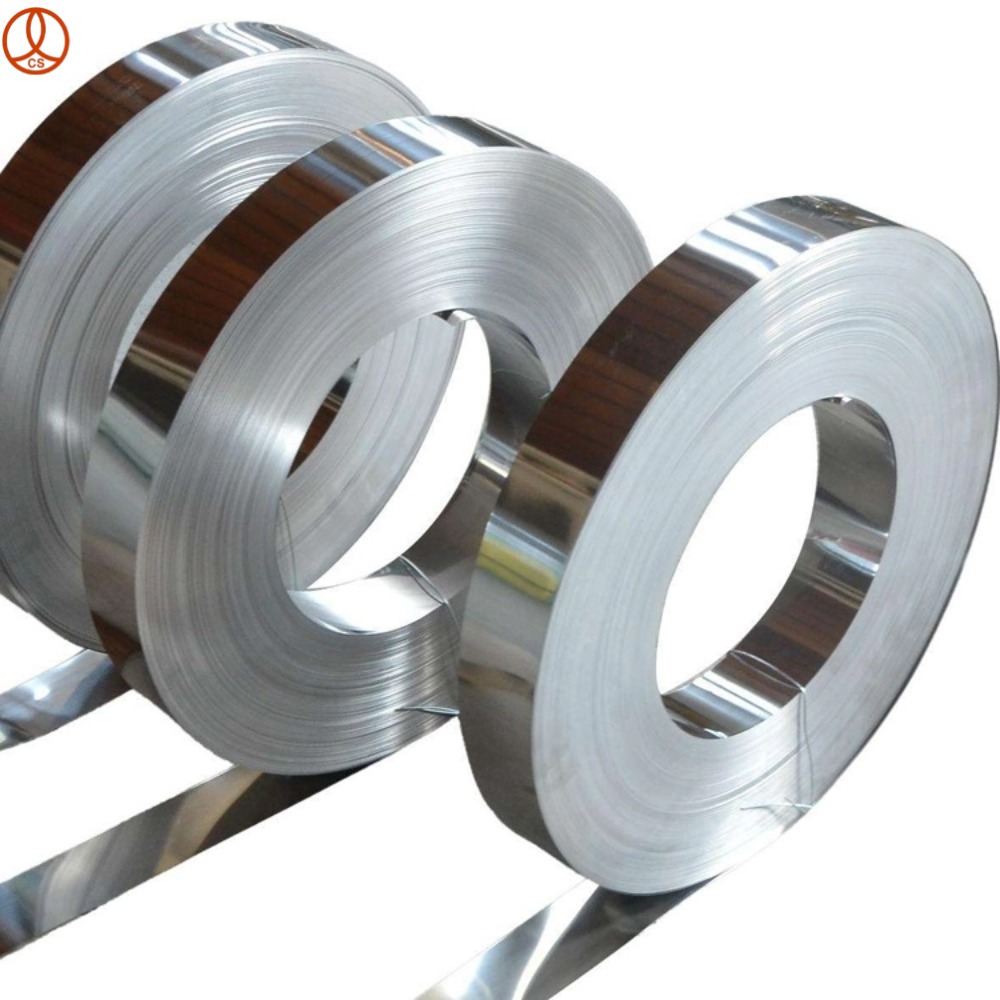

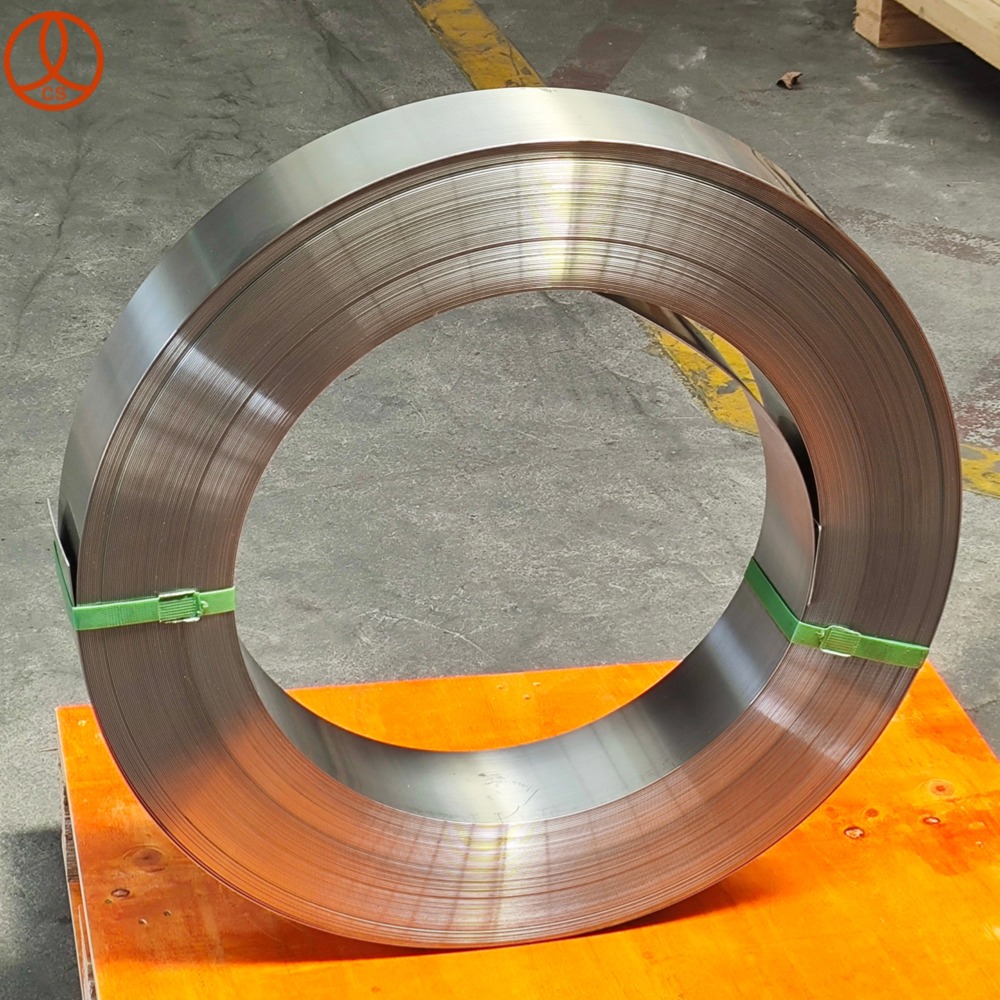

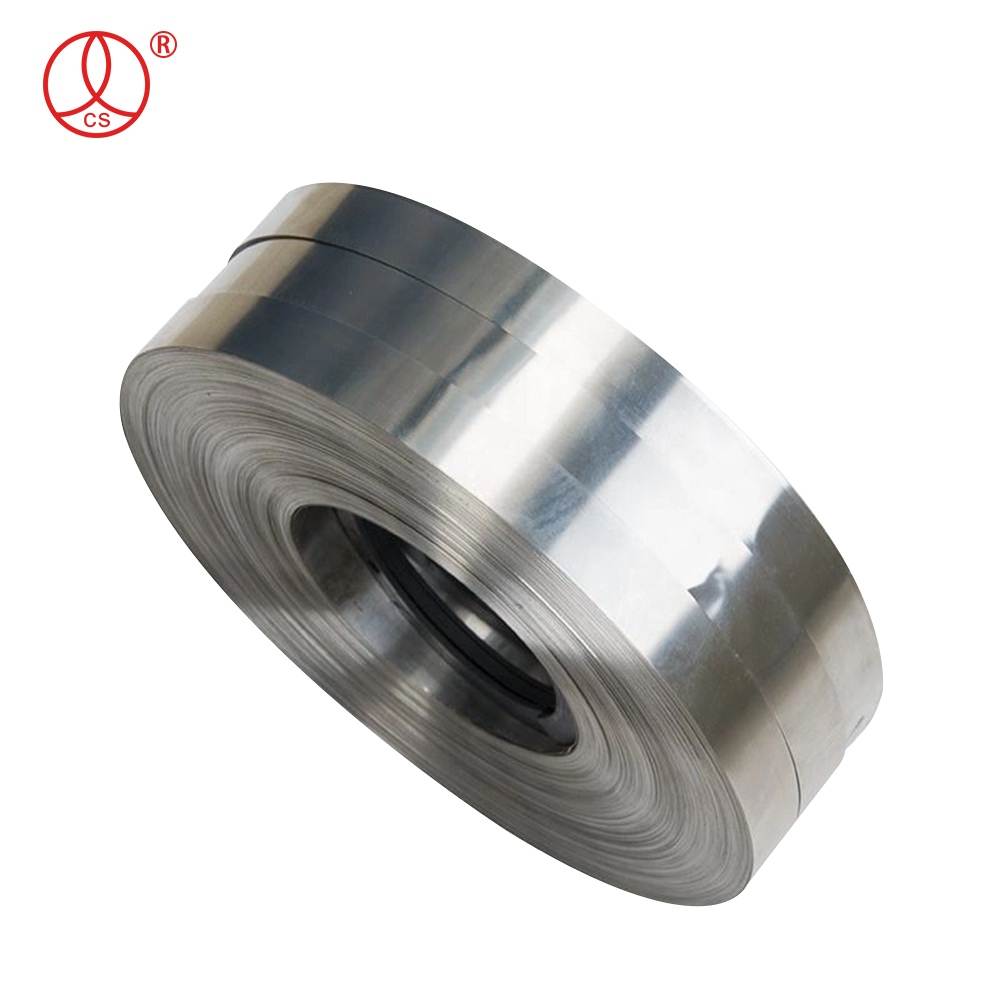

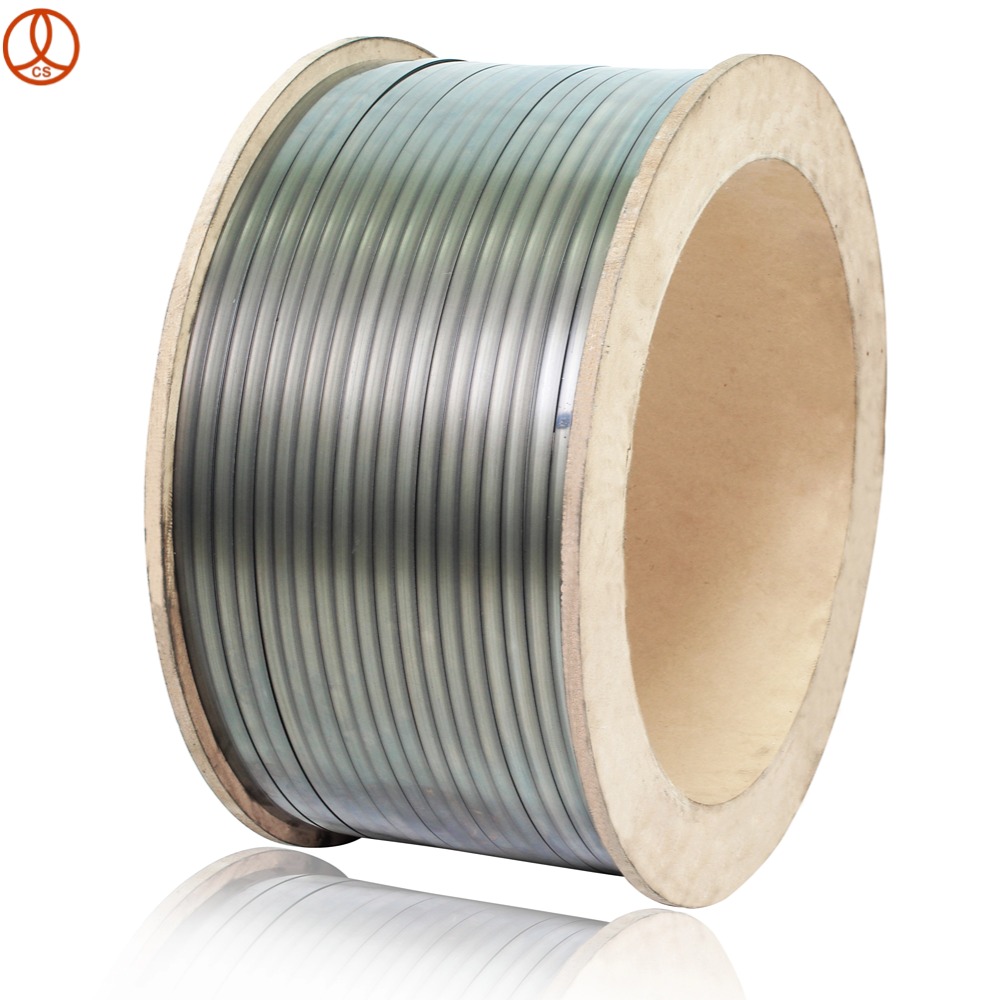

Coil |

Quality |

High Quality |

|

Composition |

Alloy Steel |

Tolerance |

±10% |

|

Processes |

Heat Treatment, Polishing, Edge Treatment, Laser Printing, Packaging |

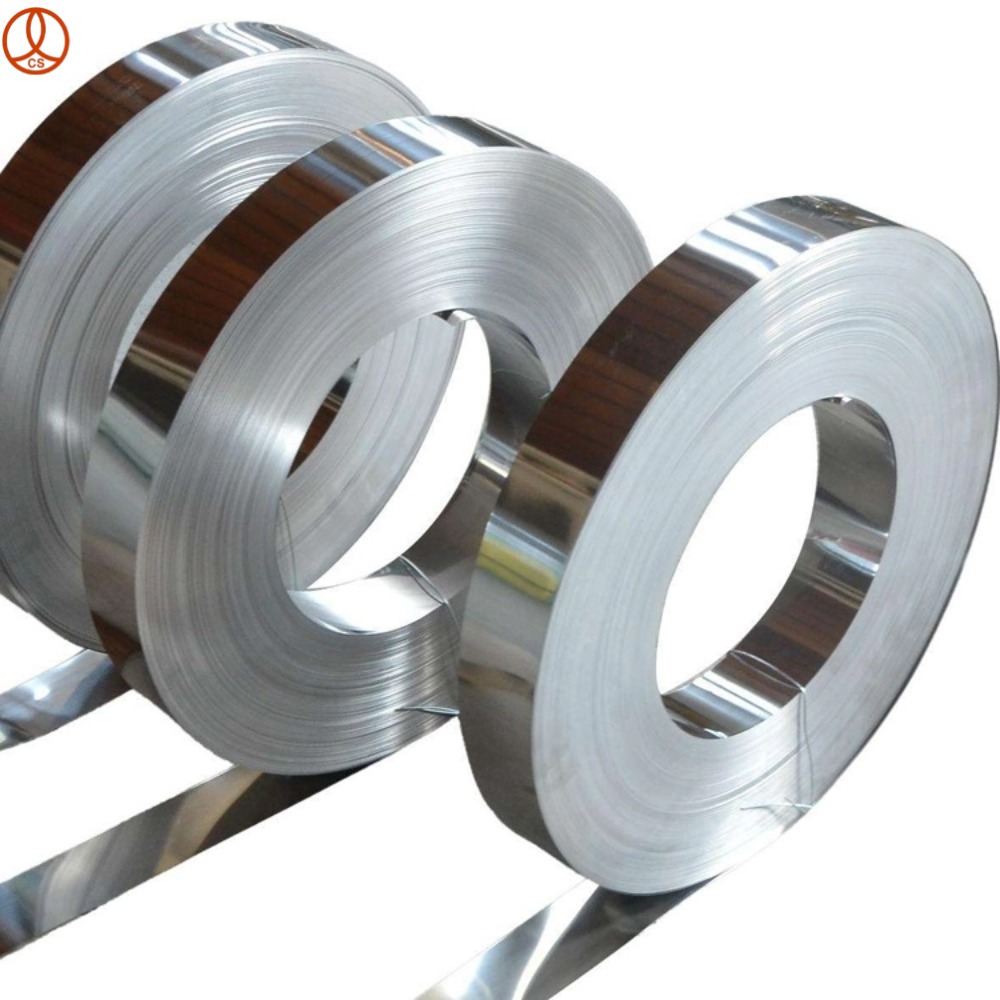

Surface Finishing |

Blue, Polished-Bright. etc |

|

Brand Name |

Chang Sheng |

Width |

16-160mm/Customized |

|

Length |

According to The Client′s Request |

Hardness |

40-50 HRC |

|

Steel Color |

White/Blue/Yellow |

MOQ |

4 Tons |

|

Delivery Time |

25-30days after receiving the Deposits |

Package |

Each Bundle with Light Oil and Anti-Rust Paper |

|

Origin |

China |

HS Code |

7312900000 |

|

Production Capacity |

20000/TONS Years |

Variety |

JP(SKS51)DE(75Ni8) |

Technical Parameters

|

Model NO. |

CS867684563 |

Standard |

ASTM, JIS, GB, AISI, DIN, BS, AISI, ASTM, DIN, JIS, GB, BS |

|

Certification |

ISO, RoHS, IBR |

Surface Treatment |

Polished |

|

Technique |

Heat Treatment |

Application |

Saw Blade, Band Saw Blade, Cutting Tools, etc |

|

Edge |

Sheared Edge/Square Edge/Round Edge/Customized, Sheared/Square/Round |

Stock |

Yes |

|

Type |

Coil |

Quality |

High Quality |

|

Composition |

Alloy Steel |

Tolerance |

±10% |

|

Processes |

Heat Treatment, Polishing, Edge Treatment, Laser Printing, Packaging |

Surface Finishing |

Blue, Polished-Bright. etc |

|

Brand Name |

Chang Sheng |

Width |

16-160mm/Customized |

|

Length |

According to The Client′s Request |

Hardness |

40-50 HRC |

|

Steel Color |

White/Blue/Yellow |

MOQ |

4 Tons |

|

Delivery Time |

25-30days after receiving the Deposits |

Package |

Each Bundle with Light Oil and Anti-Rust Paper |

|

Origin |

China |

HS Code |

7312900000 |

|

Production Capacity |

20000/TONS Years |

Variety |

JP(SKS51)DE(75Ni8) |

Product Description

If you want more details, please contact us here!

Advantages of Our High Alloy Steel Strips

1. Excellent corrosion resistance:

High-alloy steel usually contains elements such as chromium and nickel, which form a dense oxide film on the steel surface and can effectively prevent oxidation and corrosion. Therefore, high-alloy steel in harsh environments

2. High strength and toughness:

By adding different alloying elements, high alloy steel has higher strength and toughness than ordinary carbon steel. It maintains good mechanical properties at both high and low temperatures.

3. Good heat treatment adjustability:

High alloy steel can be precisely controlled for hardness, strength and toughness by adjusting process parameters such as quenching, tempering and annealing during heat treatment to meet various engineering requirements.

4. High wear resistance:

High alloy steels typically have excellent wear resistance for applications that require long working hours.

5. Good thermal stability:

High alloy steels maintain excellent strength and hardness at high temperatures.

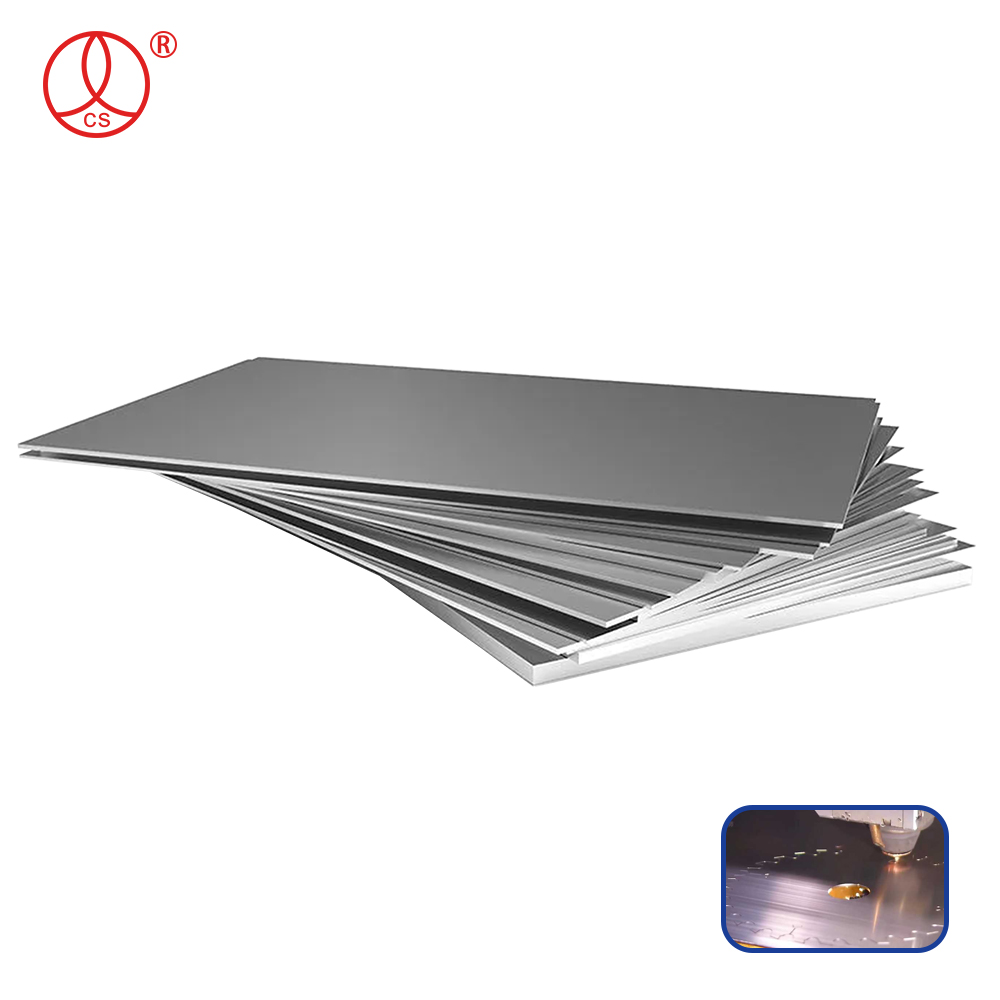

| product name | alloy steel strip |

Standard |

ASTM, JIS, GB, AISI, DIN, BS, AISI, ASTM, DIN, JIS, GB, BS |

|

Certification |

ISO, RoHS, IBR |

Surface Treatment |

Polished |

|

Technique |

Heat Treatment |

Application |

Saw Blade, Band Saw Blade,Cutting Tools.etc |

|

Edge |

Sheared Edge/Square Edge/Round Edge/Customized, Sheared/Square/Round |

Stock |

Yes |

|

Type |

Coil |

Tolerance |

±10% |

|

Processes |

Heat Treatment, Polishing, Edge Treatment, Laser Printing, Packaging |

Surface Finishing |

Blue, Polishied-Bright.etc |

|

Brand Name |

Chang Sheng |

Width |

16-160mm/Customized |

|

Length |

According to The Client′s Request |

Hardness |

40-50 HRC |

|

Steel Color |

White/Blue/Yellow |

MOQ |

4 Tons |

|

Delivery Time |

25-30days After Received The Deposits |

Package |

Each Bundle with Light Oil and Anti-Rust Paper |

|

HS Code |

7312900000 |

Variety |

JP(SKS51)DE(75Ni8) |

DongGuan ChangSheng Cutting Tools Co., Ltd. was established in 2003, is a comprehensive production enterprise integrating the production and sales of steel strip, band saw blade and band knife blade

Product quality: the company has passed the IS09001.2015 quality system certification, with 40 invention patents and certificates, national high-tech enterprises and other honorary titles, product quality is widely praised by customers.

Factory advantages: We have three factories with a total area of 100,000+ ㎡, a total annual output of 8,000 tons of products, 25 production lines, 150 professional employees.

Price advantage: we guarantee that our prices are the most competitive, because we are the source manufacturers

Customers' trust: We now cooperate with more than 4000 customers, and our products are exported to Europe, America, the Middle East, Southeast Asia, South America and other countries.

Tariff advantages: we have factories in Vietnam and can export directly from Vietnam, saving you the cost of tariffs.

We guarantee zero risk:

Product quality: guarantee product quality and undertake 6 months product warranty period.

Guaranteed delivery: we will discount your goods if there is a delay due to the delivery date.

Legal export: we comply with import and export laws and regulations so that the goods arrive safely in the destination country.

Product Description

If you want more details, please contact us here!

Advantages of Our High Alloy Steel Strips

1. Excellent corrosion resistance:

High-alloy steel usually contains elements such as chromium and nickel, which form a dense oxide film on the steel surface and can effectively prevent oxidation and corrosion. Therefore, high-alloy steel in harsh environments

2. High strength and toughness:

By adding different alloying elements, high alloy steel has higher strength and toughness than ordinary carbon steel. It maintains good mechanical properties at both high and low temperatures.

3. Good heat treatment adjustability:

High alloy steel can be precisely controlled for hardness, strength and toughness by adjusting process parameters such as quenching, tempering and annealing during heat treatment to meet various engineering requirements.

4. High wear resistance:

High alloy steels typically have excellent wear resistance for applications that require long working hours.

5. Good thermal stability:

High alloy steels maintain excellent strength and hardness at high temperatures.

| product name | alloy steel strip |

Standard |

ASTM, JIS, GB, AISI, DIN, BS, AISI, ASTM, DIN, JIS, GB, BS |

|

Certification |

ISO, RoHS, IBR |

Surface Treatment |

Polished |

|

Technique |

Heat Treatment |

Application |

Saw Blade, Band Saw Blade,Cutting Tools.etc |

|

Edge |

Sheared Edge/Square Edge/Round Edge/Customized, Sheared/Square/Round |

Stock |

Yes |

|

Type |

Coil |

Tolerance |

±10% |

|

Processes |

Heat Treatment, Polishing, Edge Treatment, Laser Printing, Packaging |

Surface Finishing |

Blue, Polishied-Bright.etc |

|

Brand Name |

Chang Sheng |

Width |

16-160mm/Customized |

|

Length |

According to The Client′s Request |

Hardness |

40-50 HRC |

|

Steel Color |

White/Blue/Yellow |

MOQ |

4 Tons |

|

Delivery Time |

25-30days After Received The Deposits |

Package |

Each Bundle with Light Oil and Anti-Rust Paper |

|

HS Code |

7312900000 |

Variety |

JP(SKS51)DE(75Ni8) |

DongGuan ChangSheng Cutting Tools Co., Ltd. was established in 2003, is a comprehensive production enterprise integrating the production and sales of steel strip, band saw blade and band knife blade

Product quality: the company has passed the IS09001.2015 quality system certification, with 40 invention patents and certificates, national high-tech enterprises and other honorary titles, product quality is widely praised by customers.

Factory advantages: We have three factories with a total area of 100,000+ ㎡, a total annual output of 8,000 tons of products, 25 production lines, 150 professional employees.

Price advantage: we guarantee that our prices are the most competitive, because we are the source manufacturers

Customers' trust: We now cooperate with more than 4000 customers, and our products are exported to Europe, America, the Middle East, Southeast Asia, South America and other countries.

Tariff advantages: we have factories in Vietnam and can export directly from Vietnam, saving you the cost of tariffs.

We guarantee zero risk:

Product quality: guarantee product quality and undertake 6 months product warranty period.

Guaranteed delivery: we will discount your goods if there is a delay due to the delivery date.

Legal export: we comply with import and export laws and regulations so that the goods arrive safely in the destination country.

DongGuan ChangSheng Cutting Tools Co., Ltd. produces premium spring steel strips specifically engineered for automotive windscreen wiper blades. Our cold-rolled steel strips deliver consistent pressure distribution and fatigue resistance for superior wiping performance.

DongGuan ChangSheng Cutting Tools Co., Ltd. manufactures premium spring strip steel for demanding applications in automotive, electronics, and industrial tooling. Our cold-rolled strips deliver exceptional elasticity, fatigue resistance, and consistent performance.

DongGuan ChangSheng Cutting Tools Co., Ltd. specializes in high-tech alloy steel strips that push the boundaries of cutting tool durability and industrial applications

DongGuan ChangSheng Cutting Tools Co., Ltd. produces high-performance saw blade steel matrix materials that set new standards in cutting tool durability and precision.

Heat Treatment High Carbon Steel Strip for Bandsaw Blade, Industrial Knife

Heat Treatment High Carbon Steel Strip for Bandsaw Blade, Industrial Knife

Heat Treatment High Carbon Steel Strip for Bandsaw Blade, Industrial Knife

Heat Treatment High Carbon Steel Strip for Bandsaw Blade, Industrial Knife

Heat Treatment High Carbon Steel Strip for Bandsaw Blade, Industrial Knife

Heat Treatment High Carbon Steel Strip for Bandsaw Blade, Industrial Knife

Heat Treatment High Carbon Steel Strip for Bandsaw Blade, Industrial Knife

Heat Treatment High Carbon Steel Strip for Bandsaw Blade, Industrial Knife

Heat Treatment High Carbon Steel Strip for Bandsaw Blade, Industrial Knife

Heat Treatment High Carbon Steel Strip for Bandsaw Blade, Industrial Knife

DongGuan ChangSheng Cutting Tools Co., Ltd. produces precision high carbon steel strips engineered for superior hardness, durability, and performance in demanding cutting tool manufacturing.

Carbon Steel Strip for Band Saw Blades – High-Performance Material for Precision Cutting [Your Company Name] manufactures premium carbon steel strips specifically engineered for band saw blade production. Our strips deliver exceptional hardness, fatigue resistance, and consistent cutting performance, making them ideal for industrial sawing applications. Key Features: ✔ High-Carbon Steel Grades – Optimized for durability and edge retention ✔ Precision Rolling & Tempering – Ensures uniform hardness (HRC XX-XX) ✔ Tight Tolerances (±0.05mm) – For stable blade operation ✔ Custom Widths & Thicknesses – Tailored to your saw blade specifications Applications: • Band saw blades for metal/wood cutting • Industrial cutting tools • Custom blade OEM production

High-performance alloy steel strips for band saw blades with enhanced chromium/vanadium content. Delivers 50% longer lifespan than carbon steel. Custom grades & sizes available. Request specs.

DongGuan ChangSheng Cutting Tools Co., Ltd. produces precision saw blade matrices – the foundational steel cores that determine the durability and cutting performance of circular saw blades. Our specialized steel strips ensure vibration-free operation and extended blade life.

DongGuan ChangSheng Cutting Tools Co., Ltd. manufactures specialized strip steel for industrial die cutters, engineered for clean, precise cuts in thick cardstock, flip-top cigarette boxes, thin paper, and gray board applications.

DongGuan ChangSheng Cutting Tools Co., Ltd. produces high-accuracy etching knife dies specifically designed for embossing die manufacturers. Our chemically-etched dies deliver intricate patterns and consistent performance for foil stamping, leather embossing, and packaging applications.

DongGuan ChangSheng Cutting Tools Co., Ltd. produces premium spring steel strips specifically engineered for automotive windscreen wiper blades. Our cold-rolled steel strips deliver consistent pressure distribution and fatigue resistance for superior wiping performance.

DongGuan ChangSheng Cutting Tools Co., Ltd. manufactures premium spring strip steel for demanding applications in automotive, electronics, and industrial tooling. Our cold-rolled strips deliver exceptional elasticity, fatigue resistance, and consistent performance.

DongGuan ChangSheng Cutting Tools Co., Ltd. specializes in high-tech alloy steel strips that push the boundaries of cutting tool durability and industrial applications

DongGuan ChangSheng Cutting Tools Co., Ltd. produces high-performance saw blade steel matrix materials that set new standards in cutting tool durability and precision.

Heat Treatment High Carbon Steel Strip for Bandsaw Blade, Industrial Knife

Heat Treatment High Carbon Steel Strip for Bandsaw Blade, Industrial Knife

Heat Treatment High Carbon Steel Strip for Bandsaw Blade, Industrial Knife

Heat Treatment High Carbon Steel Strip for Bandsaw Blade, Industrial Knife