Fabrication

is a Measure of

Success.

Technical Parameters

|

Model NO. |

CS85687684151 |

Product Name |

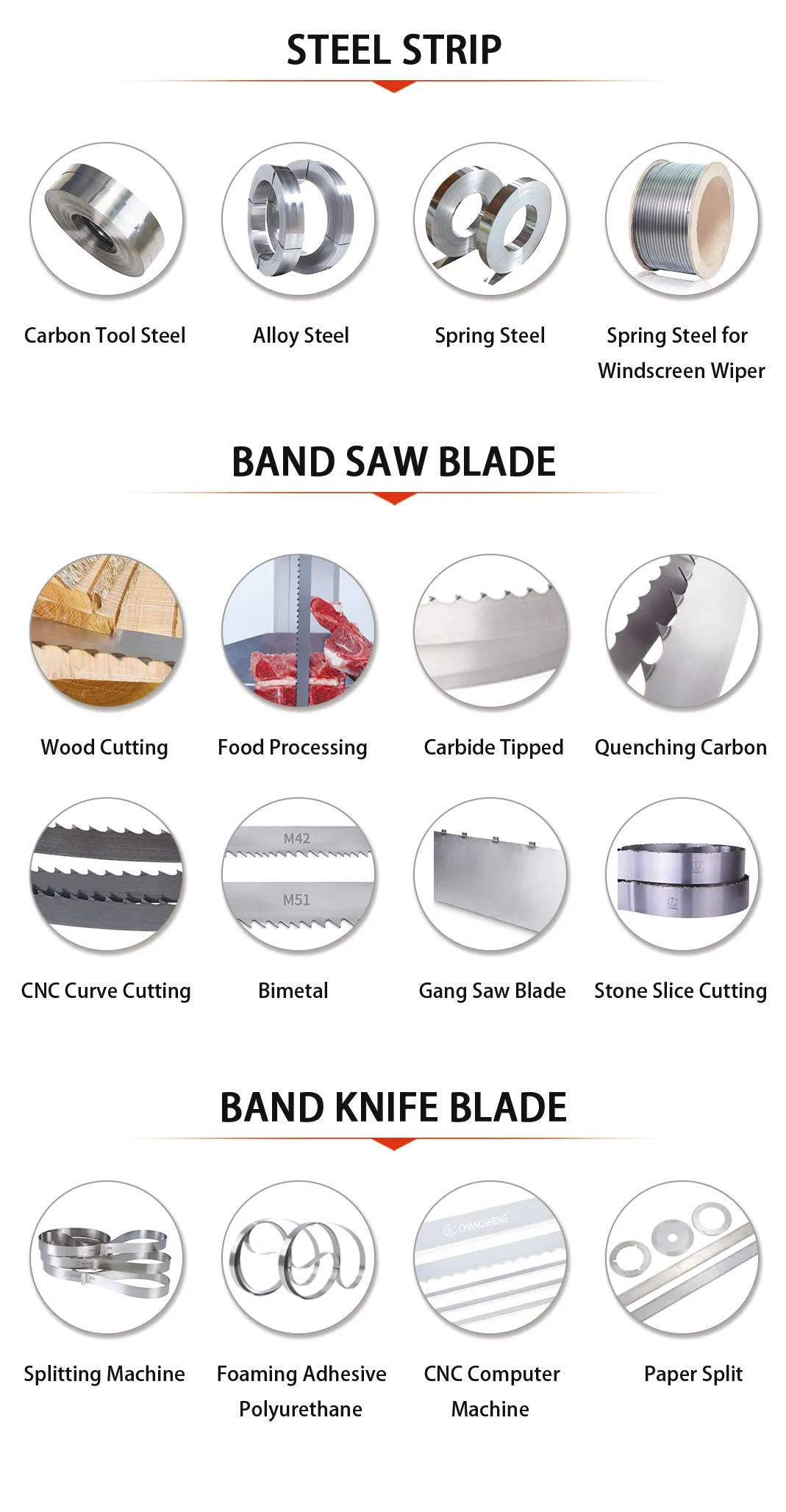

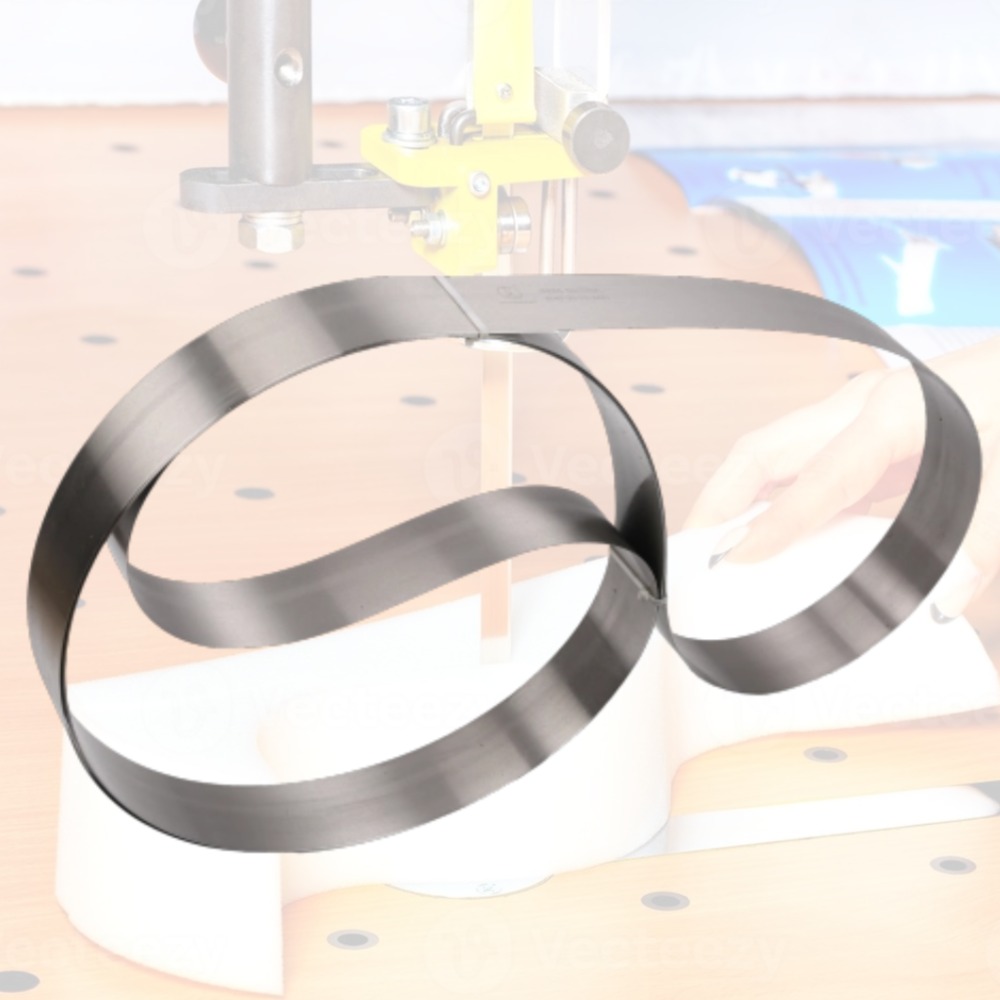

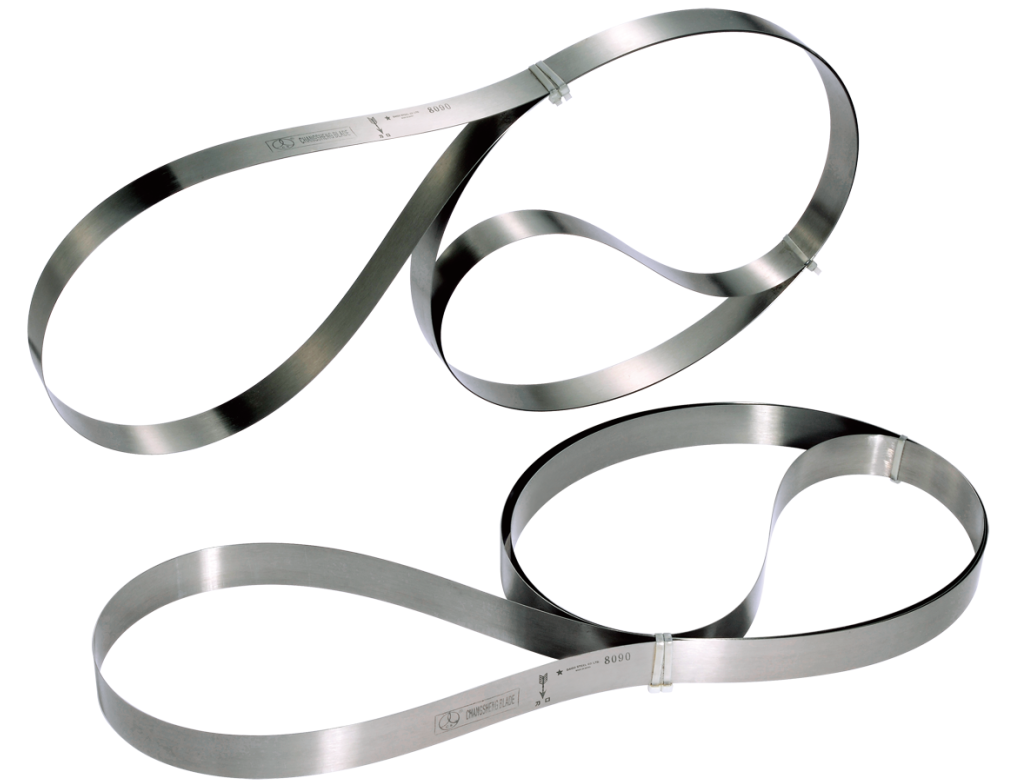

Band Knife |

|

Certification |

ISO, RoHS, IBR |

Length |

Customized |

|

Coating |

White Steel Saw Blade |

Application |

Sponge Polyurethane Factory |

|

Type |

CNC Computer Band Knife Blade |

Stock |

Yes |

|

Type |

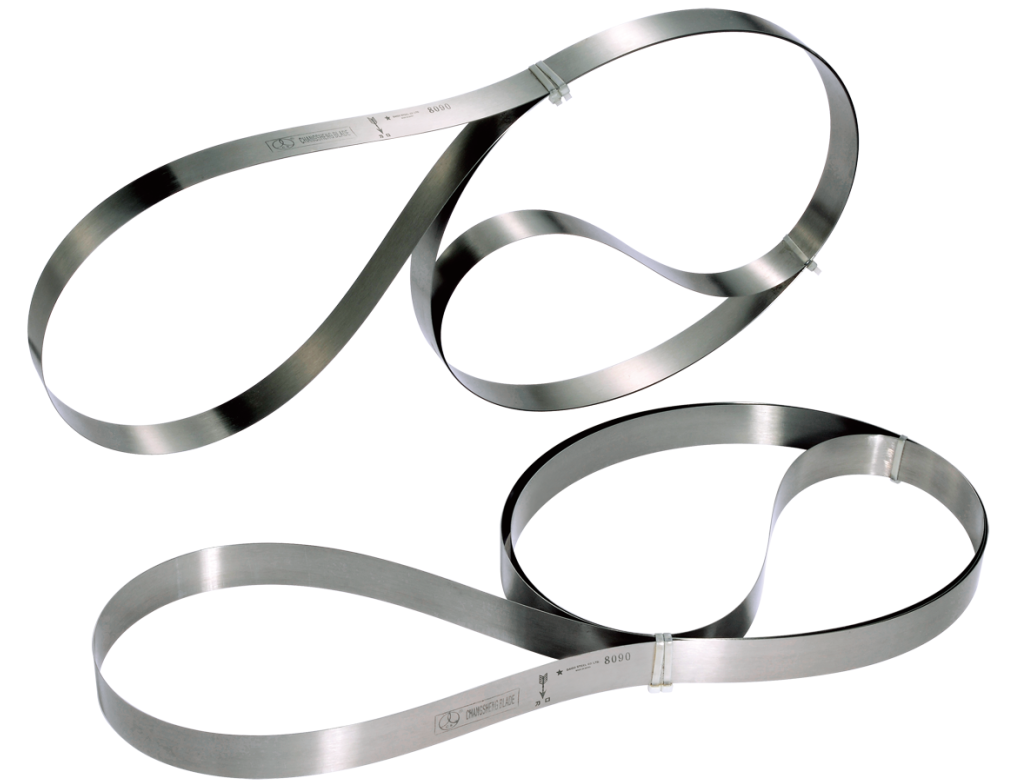

Coil |

Quality |

High Quality |

|

Material |

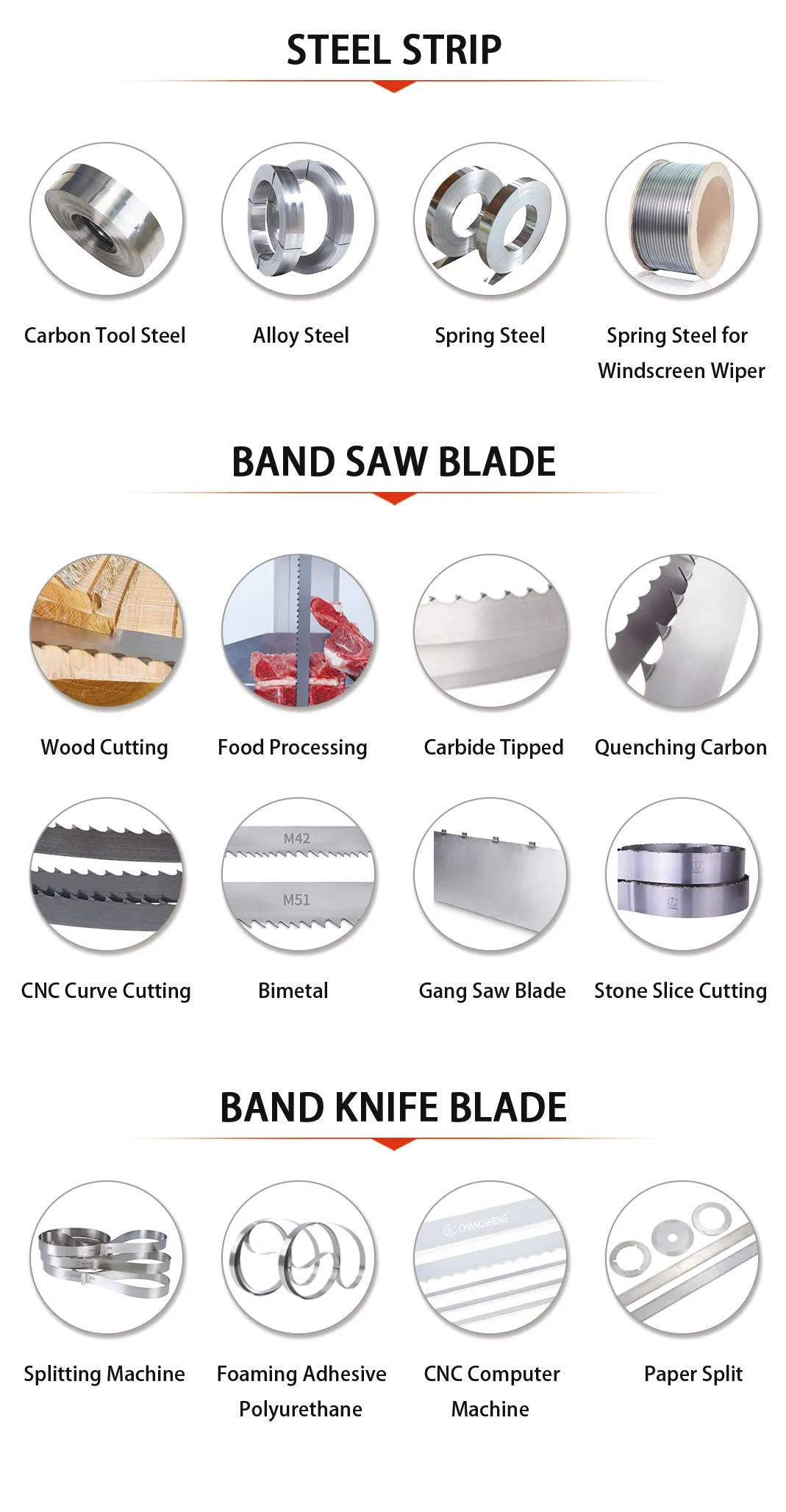

High Carbon Steel,Alloy Steel,High Alloy Steel,HSS/Customized |

Thickness |

0.6MM/Customized |

|

Brand Name |

Chang Sheng |

Width |

3-9.5MM/Customized |

|

Length |

According to The Client′s Request |

Pitch |

14/18/24P |

|

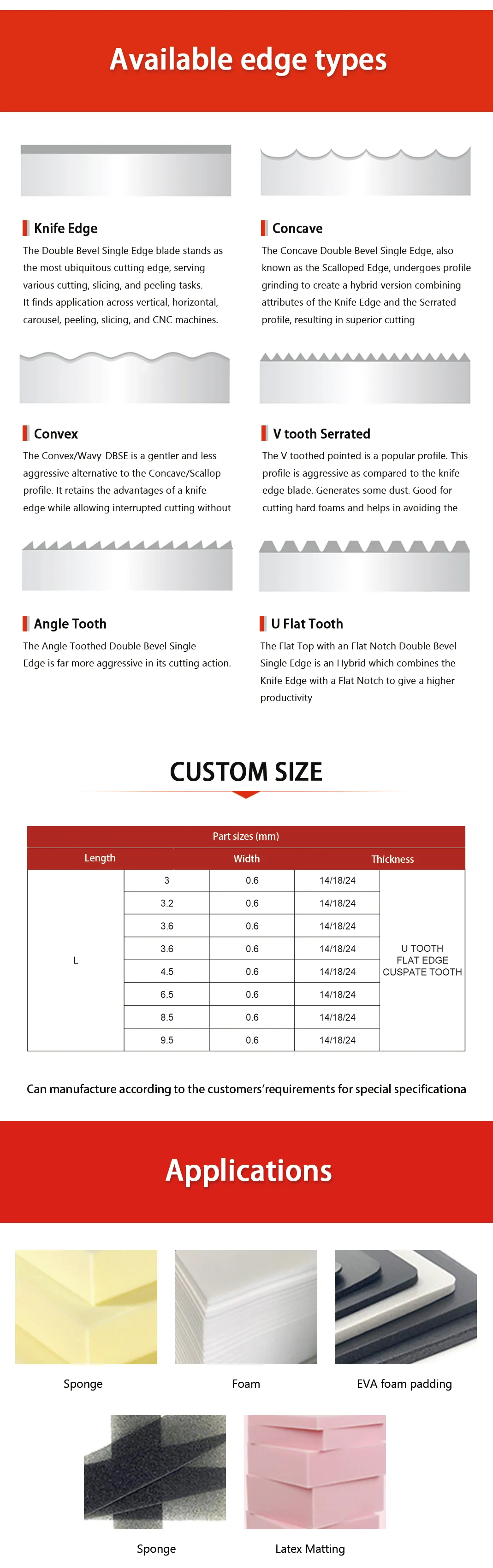

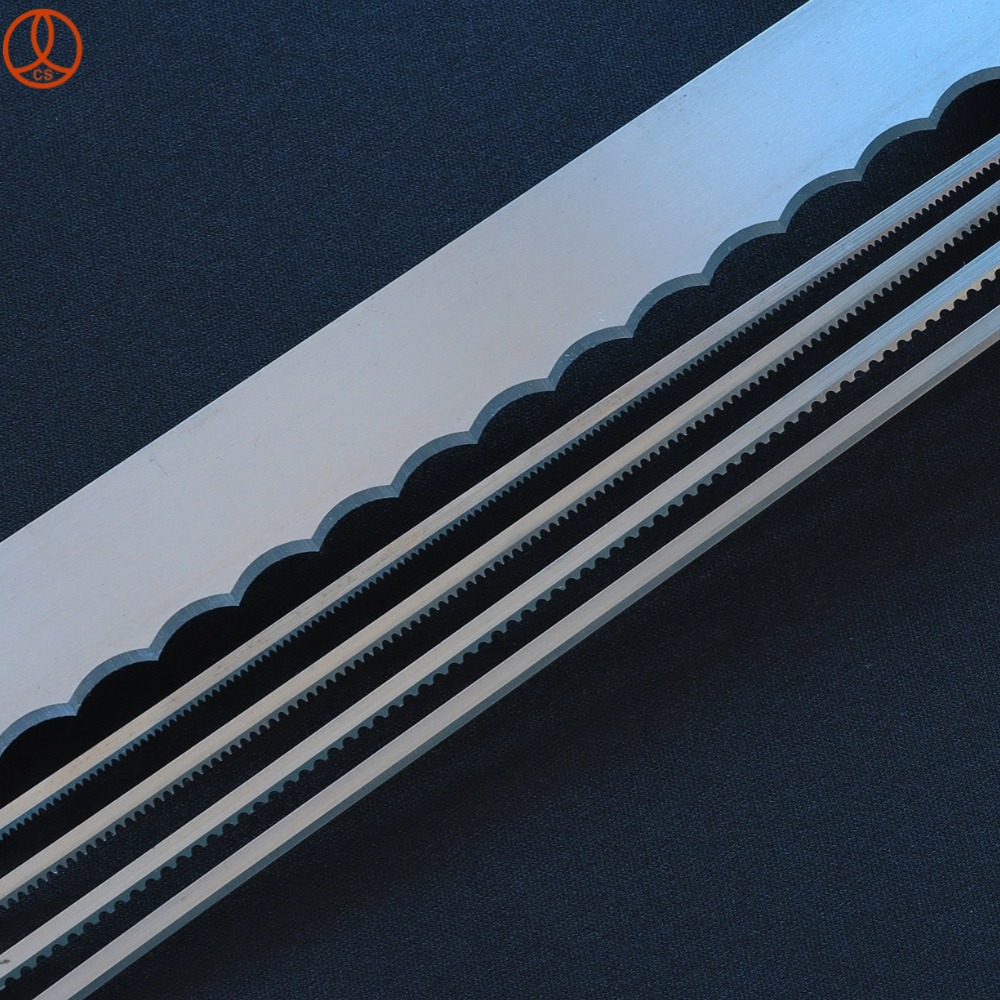

Tooth Profile |

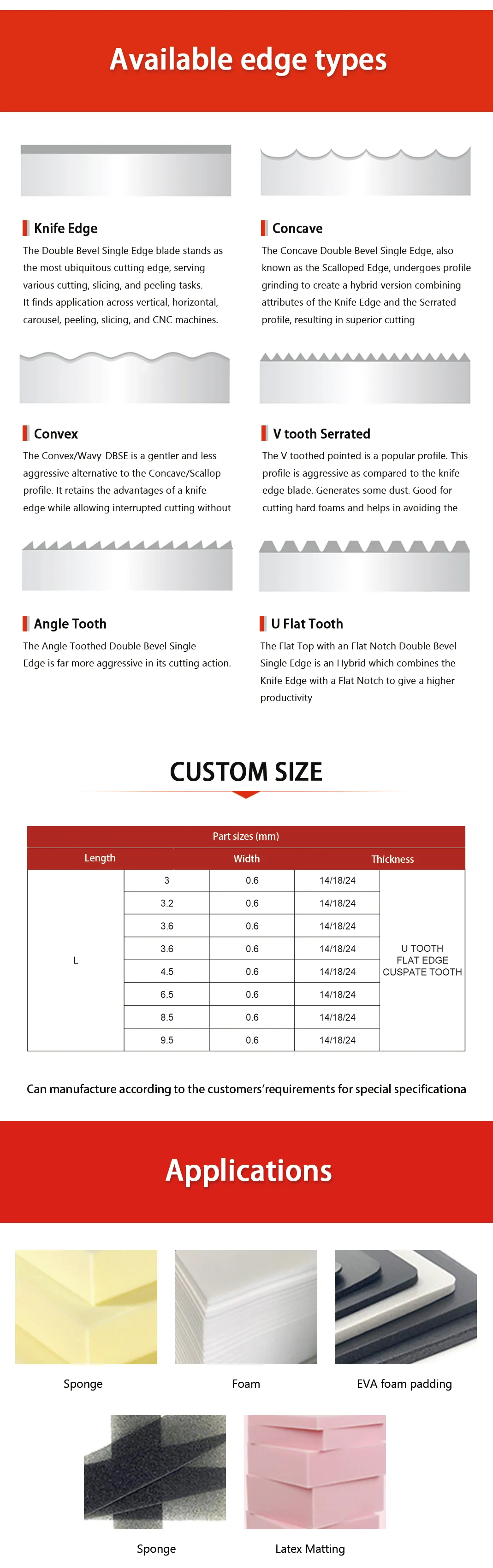

Cuspate tooth/U Tooth/Flat Tooth |

MOQ |

300 Meters |

|

Delivery Time |

25-30days After Received The Deposits |

Package |

Customized Package |

|

Origin |

China |

HS Code |

8208900000 |

|

Production Capacity |

150000m/Month |

Processing |

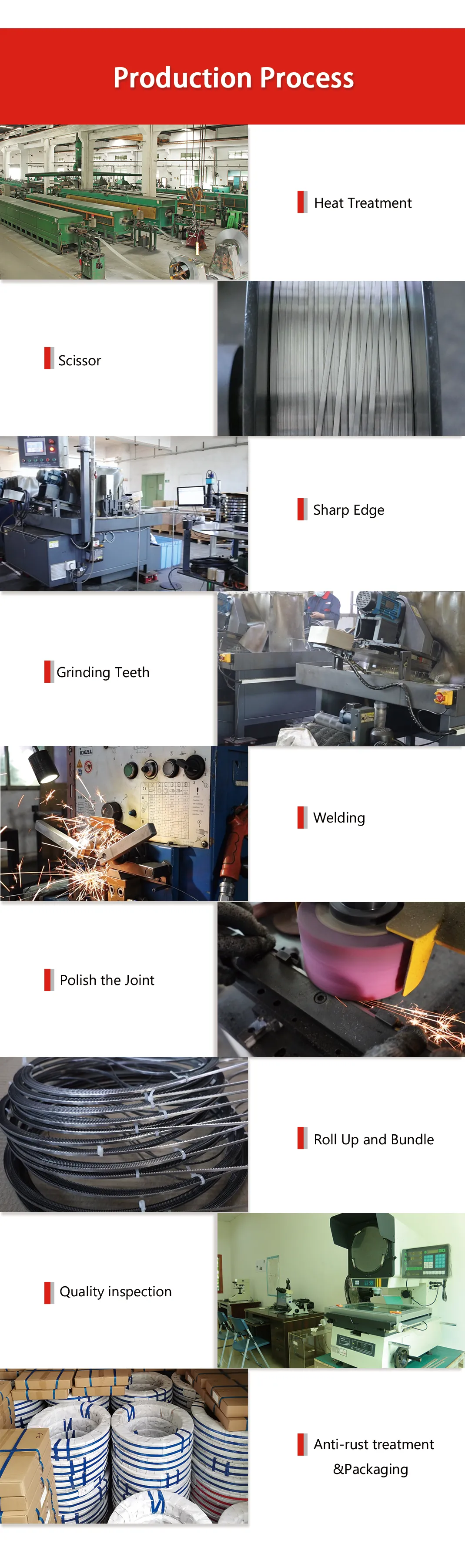

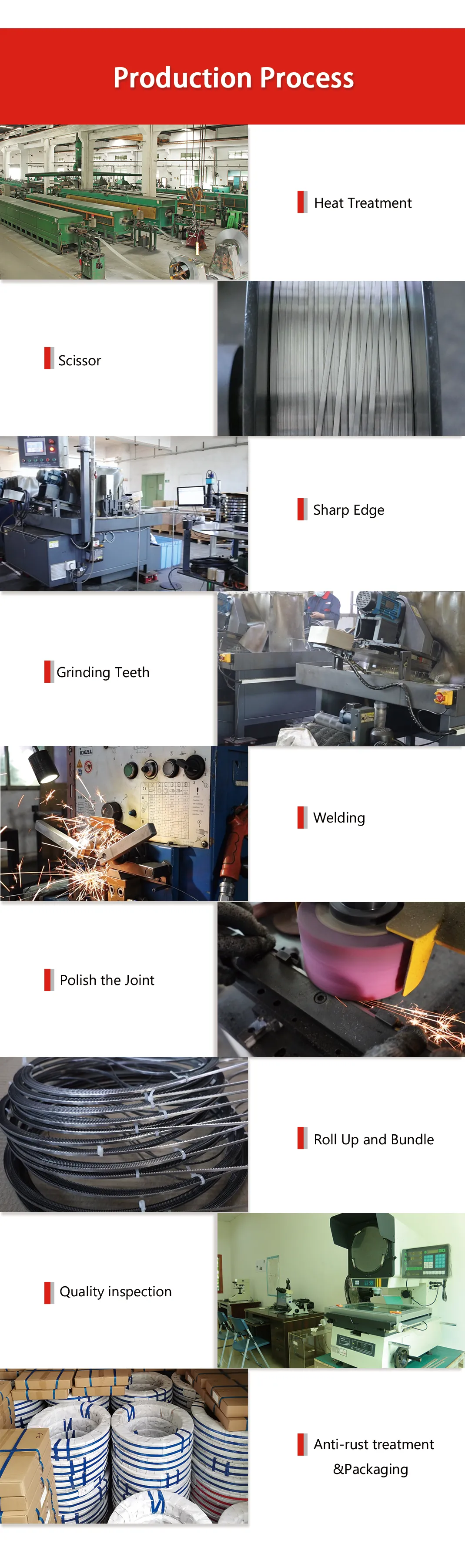

Cutting, welding, polishing, straightening the cutting edge, laser marking |

Technical Parameters

|

Model NO. |

CS85687684151 |

Product Name |

Band Knife |

|

Certification |

ISO, RoHS, IBR |

Length |

Customized |

|

Coating |

White Steel Saw Blade |

Application |

Sponge Polyurethane Factory |

|

Type |

CNC Computer Band Knife Blade |

Stock |

Yes |

|

Type |

Coil |

Quality |

High Quality |

|

Material |

High Carbon Steel,Alloy Steel,High Alloy Steel,HSS/Customized |

Thickness |

0.6MM/Customized |

|

Brand Name |

Chang Sheng |

Width |

3-9.5MM/Customized |

|

Length |

According to The Client′s Request |

Pitch |

14/18/24P |

|

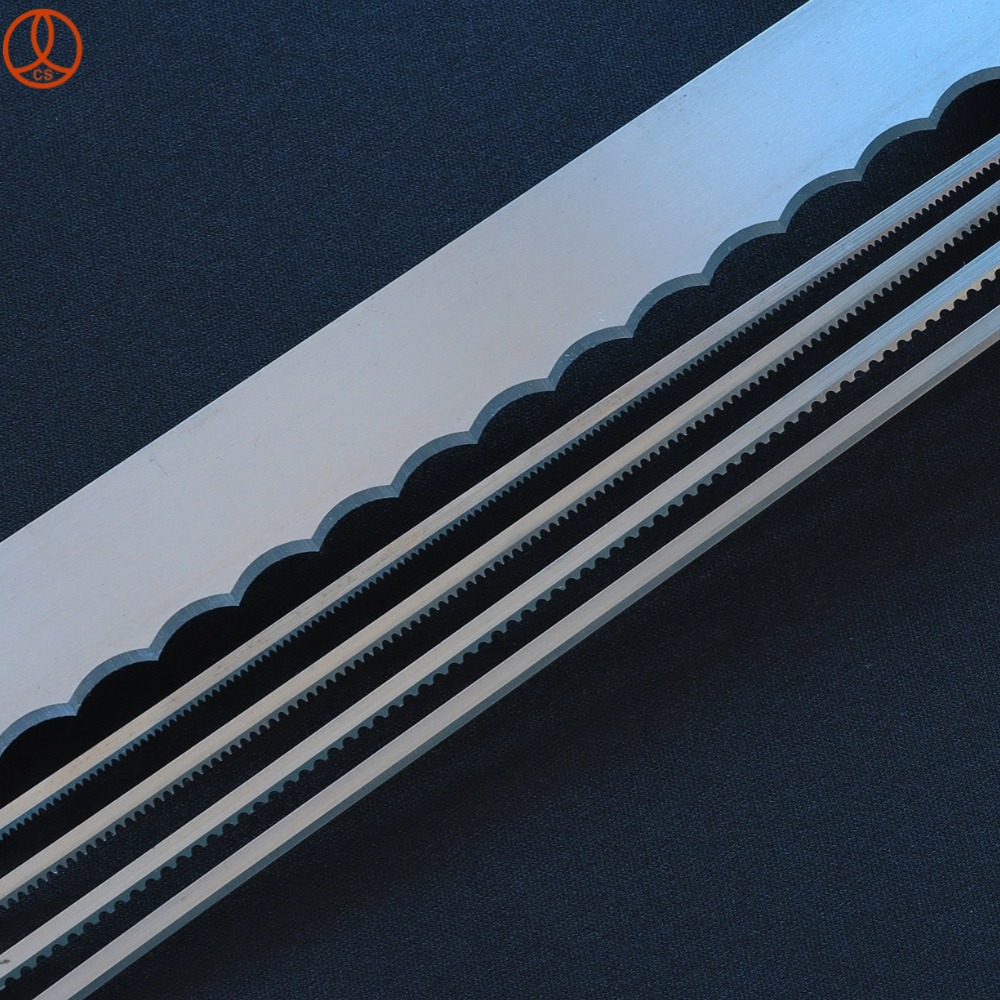

Tooth Profile |

Cuspate tooth/U Tooth/Flat Tooth |

MOQ |

300 Meters |

|

Delivery Time |

25-30days After Received The Deposits |

Package |

Customized Package |

|

Origin |

China |

HS Code |

8208900000 |

|

Production Capacity |

150000m/Month |

Processing |

Cutting, welding, polishing, straightening the cutting edge, laser marking |

Product Description

If you want more details, please contact us here!

Our Band Knife Blade Advantage

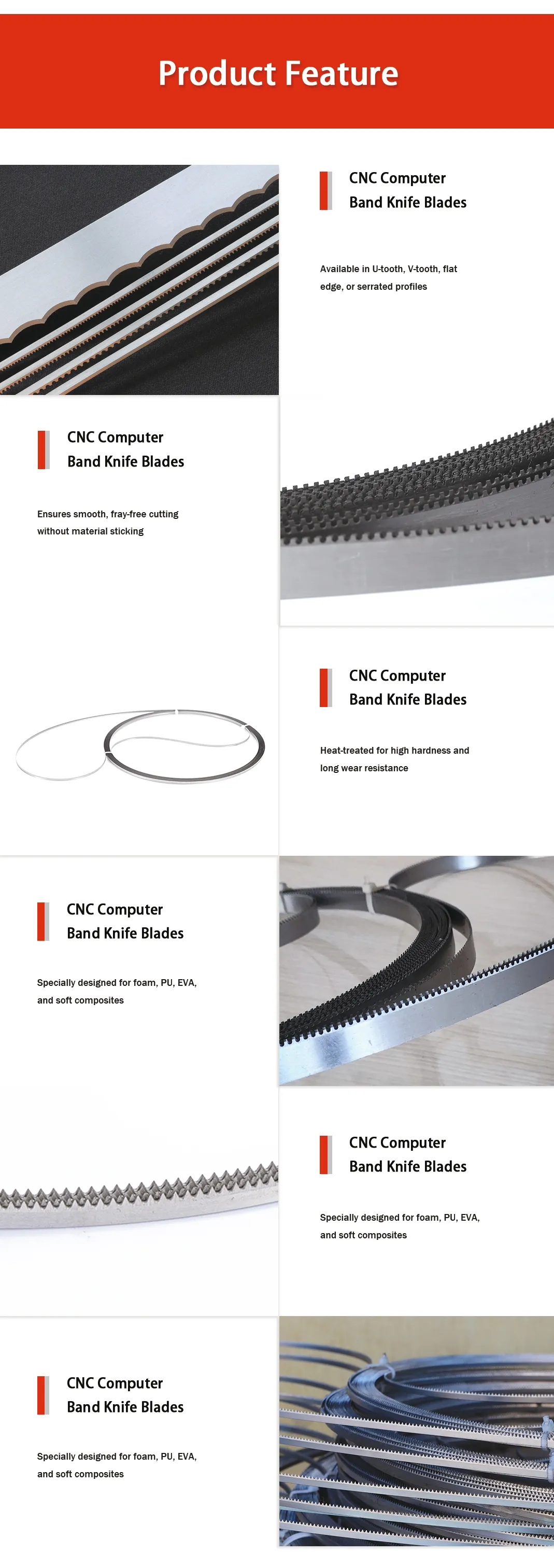

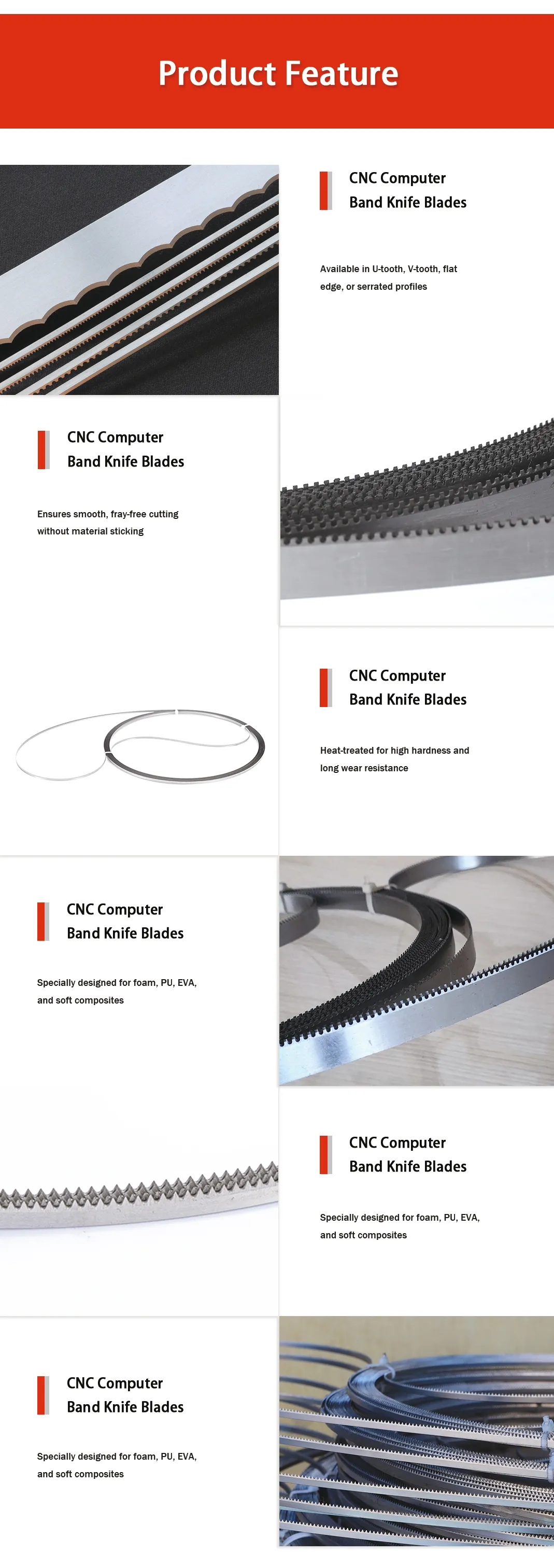

1. Advantages of Band Knife Blades Precision Cutting:

Band knife blades provide highly accurate and consistent cuts, making them ideal for applications requiring fine tolerances. They can cut intricate shapes and curves with minimal material wastage.

2. Versatility:

These blades can be used across a wide range of materials, including foam, rubber, textiles, leather, and more. This versatility makes them a preferred choice in industries like upholstery, automotive, and footwear.

3. Smooth Cutting Surface:

Band knife blades typically result in a smooth and clean cutting surface, reducing the need for additional finishing processes. This is particularly beneficial in industries like textiles and leather where the appearance of the cut edge is important.

4. Minimal Material Waste:

The thinness of the band knife blade allows for a fine cut, which minimizes material waste compared to other cutting methods. This efficiency is especially valuable in high-cost materials.

5. Durability and Longevity:

High-quality band knife blades are designed to withstand continuous use and maintain their sharpness over extended periods, reducing the frequency of replacements and downtime.

Product Description

If you want more details, please contact us here!

Our Band Knife Blade Advantage

1. Advantages of Band Knife Blades Precision Cutting:

Band knife blades provide highly accurate and consistent cuts, making them ideal for applications requiring fine tolerances. They can cut intricate shapes and curves with minimal material wastage.

2. Versatility:

These blades can be used across a wide range of materials, including foam, rubber, textiles, leather, and more. This versatility makes them a preferred choice in industries like upholstery, automotive, and footwear.

3. Smooth Cutting Surface:

Band knife blades typically result in a smooth and clean cutting surface, reducing the need for additional finishing processes. This is particularly beneficial in industries like textiles and leather where the appearance of the cut edge is important.

4. Minimal Material Waste:

The thinness of the band knife blade allows for a fine cut, which minimizes material waste compared to other cutting methods. This efficiency is especially valuable in high-cost materials.

5. Durability and Longevity:

High-quality band knife blades are designed to withstand continuous use and maintain their sharpness over extended periods, reducing the frequency of replacements and downtime.

Premium Band Knife Blades for Tissue & Hygiene Product Manufacturing Our band knife blades for tissue paper splitting are engineered for ultra-thin, high-speed cutting of delicate tissue, non-woven fabrics, and hygiene products. Made from high-grade stainless steel with precision grinding, these blades ensure clean cuts, minimal fiber dust, and extended service life—critical for tissue paper converting lines.

Ultra-Precision Band Knife Blades for Tissue Paper Converting | Hygienic Cutting Solutions Industry-Leading Performance for Tissue & Hygiene Manufacturing Our specialized band knife blades for tissue paper splitting (卫deliver micro-precise cutting performance for high-speed tissue converting lines. Engineered with medical-grade stainless steel and nano-level polishing, these blades ensure feather-edge sharpness and contamination-free operation for sensitive hygiene applications.

High-Performance CNC Band Knife Blades for Precision Cutting Our band knife blades for CNC machines are engineered for ultra-precise, computer-controlled cutting of soft materials like foam, rubber, textiles, and composites. Designed to integrate seamlessly with CNC cutting systems, these blades deliver exceptional accuracy, smooth operation, and long-lasting sharpness—perfect for industrial automation and digital fabrication.

Precision-Ground CNC Band Knife Blades for Digital Fabrication | Industrial Cutting Excellence Engineered for High-Speed CNC Cutting Systems Our premium CNC band knife blades are precision-crafted for computer-controlled cutting applications requiring micron-level accuracy. Manufactured using aerospace-grade tool steels and Swiss grinding technology, these blades deliver unmatched performance in automated production environments.

DongGuan ChangSheng cutting tools Co., Ltd. manufactures industrial-grade band knife blades specifically engineered for splitting machines in leather, foam, and composite material processing. Our blades deliver razor-sharp precision and extended service life for demanding production environments.

DongGuan ChangSheng cutting tools Co., Ltd. manufactures high-performance band knife blades specifically designed for dissecting machines in leather, textile, and foam processing industries. Our blades ensure clean, precise cuts with exceptional durability for high-volume production.

DongGuan ChangSheng cutting tools Co., Ltd. manufactures specialized band knife blades engineered for sponge and foam cutting machines, delivering clean, smooth cuts in polyurethane, memory foam, and industrial sponges.

DongGuan ChangSheng cutting tools Co., Ltd. manufactures high-performance band knife blades specifically engineered for cutting EVA foam, rubber sheets, and composite materials with clean, smooth edges.

DongGuan ChangSheng cutting tools Co., Ltd. manufactures high-performance band knife blades specifically designed for cutting tissue paper, cardboard, and packaging materials with exceptional precision and minimal fiber tear.

DongGuan ChangSheng cutting tools Co., Ltd. manufactures precision scallop-edge band knife blades featuring patented wave-shaped cutting technology for reduced friction and enhanced material handling.

DongGuan ChangSheng cutting tools Co., Ltd. manufactures industrial-grade band knife blades specifically engineered for shearing machines, delivering clean, efficient cuts in textiles, rubber, and composite materials.

DongGuan ChangSheng cutting tools Co., Ltd. manufactures high-performance wavy-edge band knife blades designed for superior material handling in foam, rubber, and composite cutting operations.

Premium Band Knife Blades for Splitting – Precision & Durability As a trusted manufacturer of industrial cutting tools, we specialize in high-performance band knife blades designed for leather splitting, fabric cutting, and foam processing. Our blades ensure razor-sharp precision, long-lasting performance, and smooth operation in splitting machines.

Premium Band Knife Blades for Splitting – Precision & Durability As a trusted manufacturer of industrial cutting tools, we specialize in high-performance band knife blades designed for leather splitting, fabric cutting, and foam processing. Our blades ensure razor-sharp precision, long-lasting performance, and smooth operation in splitting machines.

DongGuan ChangSheng cutting tools Co., Ltd. manufactures high-performance band knife blades specifically designed for dissecting machines in leather, textile, and foam processing industries. Our blades ensure clean, precise cuts with exceptional durability for high-volume production.

DongGuan ChangSheng cutting tools Co., Ltd. manufactures high-performance band knife blades specifically designed for dissecting machines in leather, textile, and foam processing industries. Our blades ensure clean, precise cuts with exceptional durability for high-volume production.

Premium Band Knife Blades for Sponge Splitting – Precision Cutting for Foam & Soft Materials Our high-performance band knife blades for sponge splitting deliver razor-sharp, smooth, and consistent cuts for foam, sponge, and soft material processing. Engineered from high-grade alloy steel, these blades ensure durability, minimal kerf loss, and extended service life—perfect for foam splitting machines in upholstery, mattress, and packaging industries.

High-Quality Band Knife Blades for Sponge Splitting Machines | Precision Cutting Solutions Our band knife blades for sponge splitting are specially designed for high-precision foam and sponge cutting applications. Manufactured from premium alloy steel, these blades provide exceptional sharpness, durability, and smooth operation—ensuring clean, consistent cuts with minimal material waste.

Precision Band Knife Blades for EVA & Rubber Splitting | Industrial-Grade Cutting Solutions Our high-performance band knife blades for EVA/Rubber splitting are engineered to deliver clean, precise cuts through tough elastomeric materials. Perfect for EVA foam, rubber sheets, and synthetic materials, these blades maintain exceptional sharpness and durability even under continuous industrial use.

Premium Band Knife Blades for EVA/Rubber Splitting | Precision Cutting Solutions Our industrial-grade band knife blades for EVA/Rubber splitting (EVA Rubber带刀) deliver unmatched performance in processing elastomeric materials. Engineered with high-carbon alloy steel and advanced heat treatment, these blades offer exceptional durability and cutting precision for demanding applications.

Premium Band Knife Blades for Tissue & Hygiene Product Manufacturing Our band knife blades for tissue paper splitting are engineered for ultra-thin, high-speed cutting of delicate tissue, non-woven fabrics, and hygiene products. Made from high-grade stainless steel with precision grinding, these blades ensure clean cuts, minimal fiber dust, and extended service life—critical for tissue paper converting lines.

Ultra-Precision Band Knife Blades for Tissue Paper Converting | Hygienic Cutting Solutions Industry-Leading Performance for Tissue & Hygiene Manufacturing Our specialized band knife blades for tissue paper splitting (卫deliver micro-precise cutting performance for high-speed tissue converting lines. Engineered with medical-grade stainless steel and nano-level polishing, these blades ensure feather-edge sharpness and contamination-free operation for sensitive hygiene applications.

High-Performance CNC Band Knife Blades for Precision Cutting Our band knife blades for CNC machines are engineered for ultra-precise, computer-controlled cutting of soft materials like foam, rubber, textiles, and composites. Designed to integrate seamlessly with CNC cutting systems, these blades deliver exceptional accuracy, smooth operation, and long-lasting sharpness—perfect for industrial automation and digital fabrication.

Precision-Ground CNC Band Knife Blades for Digital Fabrication | Industrial Cutting Excellence Engineered for High-Speed CNC Cutting Systems Our premium CNC band knife blades are precision-crafted for computer-controlled cutting applications requiring micron-level accuracy. Manufactured using aerospace-grade tool steels and Swiss grinding technology, these blades deliver unmatched performance in automated production environments.

DongGuan ChangSheng cutting tools Co., Ltd. manufactures industrial-grade band knife blades specifically engineered for splitting machines in leather, foam, and composite material processing. Our blades deliver razor-sharp precision and extended service life for demanding production environments.

DongGuan ChangSheng cutting tools Co., Ltd. manufactures high-performance band knife blades specifically designed for dissecting machines in leather, textile, and foam processing industries. Our blades ensure clean, precise cuts with exceptional durability for high-volume production.

DongGuan ChangSheng cutting tools Co., Ltd. manufactures specialized band knife blades engineered for sponge and foam cutting machines, delivering clean, smooth cuts in polyurethane, memory foam, and industrial sponges.

DongGuan ChangSheng cutting tools Co., Ltd. manufactures high-performance band knife blades specifically engineered for cutting EVA foam, rubber sheets, and composite materials with clean, smooth edges.